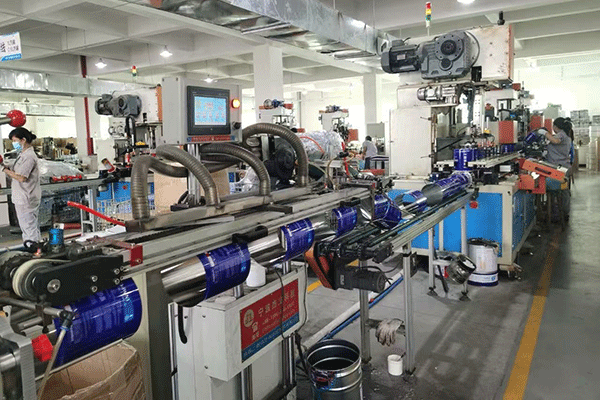

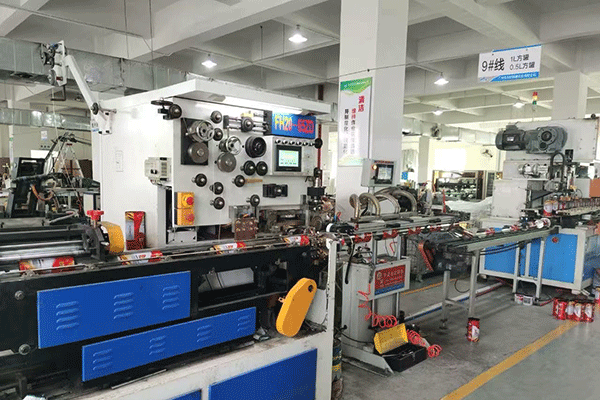

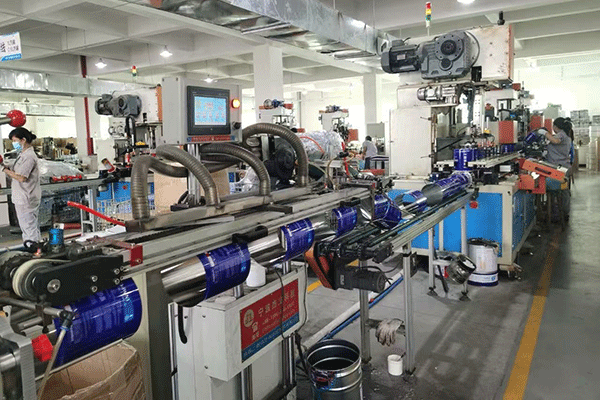

Explore our cutting-edge tin aerosol can manufacturing process that is designed to deliver quality and precision tin cans as well as innovative packaging with brand influence for your business.

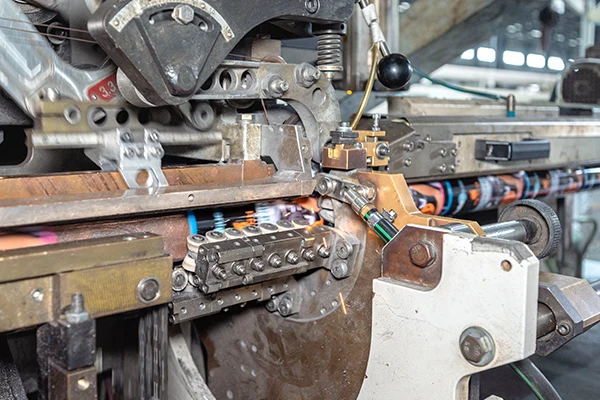

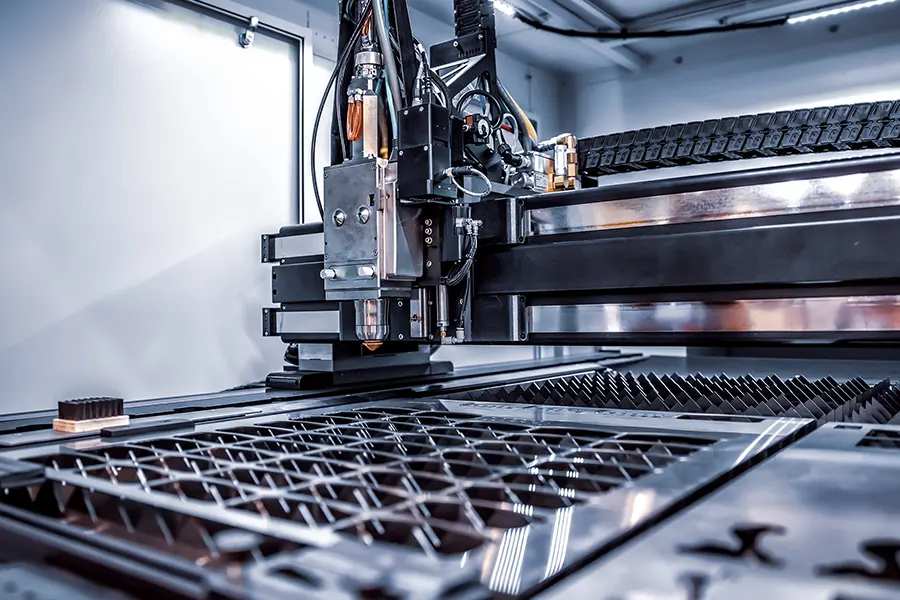

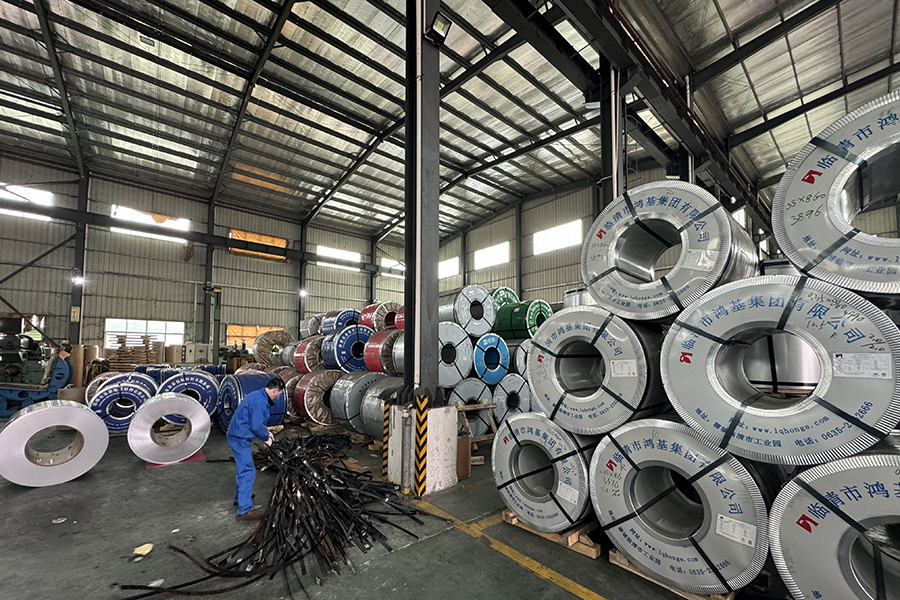

Our manufacturing process begins with meticulous raw material preparation. We source high-quality tinplate from well-known supplies to ensure the durability and integrity of our tin aerosol cans.

| Raw Materials | Tamanho | Density | Solid Content | Spot Check |

|---|---|---|---|---|

| Aço | ✔ | ✔ | - | ✔ |

| White porcelain oil | - | ✔ | ✔ | ✔ |

| Sealant | - | ✔ | ✔ | ✔ |

| Plastic handles | - | ✔ | ✔ | ✔ |

| ... | ... | ... | ... | ... |