Aerosol filling machines are an integral part of aerosol production and packaging, from spray paint to household cleaners and even personal care products. These advanced machines play a vital role in ensuring the safety, efficiency and precision of the aerosol packaging process. Whether you are in the packaging industry or are simply curious about how aerosol products are made, understanding these machines is essential.

What is an aerosol filling machine?

Aerosol filling machines are mainly special equipment used to fill aerosol products into aerosol cans. Products include paints, odświeżacze powietrza, rust removers, smary, itp. that are common in our daily lives. These machines are specially designed by professional manufacturers to accurately and safely fill various types of liquids into aerosol cans, maintaining the efficiency, accuracy and integrity of products and containers.

Key Components of Aerosol Filling Machines

Aerosol filling machines consist of several key components that work together to ensure efficient and accurate filling:

Filling head: The component that injects the product into the can. It must be precise to avoid overfilling or underfilling.

Capper: This component seals the valve onto the can, ensuring it is airtight and secure.

Propellant Filler: Responsible for adding propellant to the can, this component is critical to the performance of the product.

Control System: The brain of the machine, overseeing the entire process to ensure everything runs smoothly and to specification.

Types of Aerosol Filling Machines

There are several types of aerosol filling machines, each designed for a specific application. The most common types include:

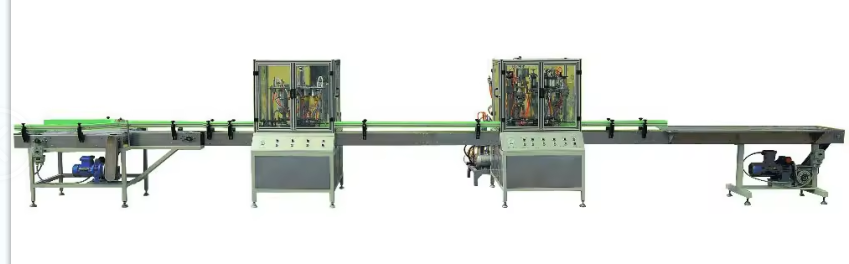

Fully Automatic Aerosol Filling Machine

A fully automatic aerosol filling machine is an advanced device specifically designed to efficiently and accurately fill liquid or gas products into aerosol cans. The machine integrates multiple processes such as filling, opieczętowanie, pressurization and testing, all of which are automatically completed by a computer control system without human intervention. Fully automatic aerosol filling machines are able to process a large number of products in a short period of time, suitable for large-scale production needs, especially in industries such as cosmetics, medycyna, chemicals and household cleaning. By reducing manual operations, fully automatic aerosol filling machines not only improve production efficiency, but also ensure product quality consistency, reduce error rates and waste in the production process, and enable companies to respond to market demand at a lower cost and higher speed.

Semi-automatic Aerosol Filling Machine

Semi-automatic aerosol filling machines are a type of equipment that combines manual operation and automation functions, designed for small and medium-scale production. The equipment usually includes an automatic filling and pressurizing system, and requires the operator to perform some manual operations, such as placing the aerosol can, starting the filling process or sealing.

Ręczne napełnianie aerozolu

A manual aerosol filling machine is a small device used to fill liquid or gas products into aerosol cans. Unlike automated equipment, manual aerosol filling machines require operators to manually perform each step, including filling the product into the can, opieczętowanie, and inspection. This equipment has a simple structure and is easy to operate. It is usually used in small batch production or laboratory testing stages. Due to its low cost and high flexibility, it is particularly suitable for small and medium-sized enterprises or individual merchants, especially when producing small batches and multiple varieties of products. Manual aerosol filling machines not only meet specific production needs, but also provide higher operational control, allowing users to flexibly adjust filling volume and production speed.

This 3 type of machine has a variety of uses, from manufacturing special aerosol products to manufacturing daily consumer aerosols. Dlatego, if you are engaged in the selection and use of aerosol application filling equipment, then choosing one of the above aerosol filling machines according to the situation of your own company will be your best choice.

How Do Aerosol Filling Machines Work?

The aerosol filling machine process usually starts with the preparation of empty cans, which are automatically transported to the filling position. The machine first injects a predetermined amount of liquid product into the can, and then adds propellant, which is usually compressed or liquefied gas, through a special nozzle. The can mouth is then sealed by an automatic sealing device to ensure that the pressure inside the can remains stable. In fully automatic systems, this process includes automated quality inspection to ensure that the filling amount and sealing of each can meet the standards.

Advantages of aerosol filling machines

The many advantages of aerosol filling machines make them widely used in the production process of many industries. Here are its main advantages:

1、High production efficiency: Through automated operation, the aerosol filling machine can process a large number of products in a short time, significantly increasing the production speed and meeting the needs of large-scale production.

2、Accuracy and consistency: The equipment can accurately control the filling volume and pressure to ensure the consistency of the contents of each aerosol can, reducing errors and scrap rates in production.

3、Operational safety: . automated filling process reduces human intervention and reduces risks in operations, especially when handling high-pressure propellants and chemicals.

4、Strong adaptability: The aerosol filling machine can adapt to different types of products and packaging needs, such as various liquids, gases and propellants, to meet diverse market needs.

5、Cost savings: Automated production reduces dependence on labor and reduces labor costs. At the same time, material waste and defective product rates are reduced, further reducing production costs.

6、Quality control: Modern aerosol filling machines are usually equipped with intelligent control systems that can monitor the production process in real time and conduct automated quality inspections to ensure that the quality of each batch of products meets standards.

7、Environmental protection: Some aerosol filling machines use environmentally friendly propellants and processes, which help reduce the impact on the environment and meet the requirements of modern environmentally friendly production.

These advantages make this equipment widely used in cosmetics, Farmaceutyki, chemicals and other industries.

Why are aerosol filling machines so important?

Aerosol filling machines are essential to maintaining product consistency, bezpieczeństwo, and efficiency during the packaging process. They ensure that each aerosol can is filled to precise specifications, which is critical to product performance and consumer safety. In addition, these machines help manufacturers meet industry regulations and standards.

Wniosek

They are the cornerstone of the aerosol packaging industry, ensuring that products are filled accurately, safely, and efficiently. Whether you are an industry insider or simply interested in the technology, understanding these machines can provide you with valuable insights into the world of aerosol products. By choosing the right machines and maintaining them properly, manufacturers can achieve high-quality production and meet the demands of an ever-changing market.