Puszki aerozolowe are a common sprayer in daily life, used to store and spray liquids, and are widely used in personal care, detergent products, chemicals and other fields. Aerosol cans provide more convenience for our lives. Jednakże, its production is a complex and delicate process. The aerosol can manufacturing process mainly includes material preparation, spraying inner wall, appearance design, assembly and testing, itp., which requires manufacturers to strictly control multiple links to bring high-quality products to users.

Material selection of aerosol cans

Pierwszy, the production of aerosol cans requires the preparation of the required materials. Generally speaking, the main components of aerosol cans are the can body and the nozzle. The can body is usually made of tinplate, aluminium, plastic and other materials, and the nozzle is made of plastic material. Aerosol can manufacturers will decide which materials to use and conduct strict quality inspections based on the aerosol used by users to ensure that the manufactured finished products have good quality and reliable performance

Aerosol can design

The design of an aerosol can is not only about its appearance, but also involves functionality, safety and user experience. An excellent aerosol can design should meet the storage and spraying requirements of aerosols while ensuring the safety and convenience of users. The following are some key considerations for aerosol can design

Aerosol can size

The size of an aerosol can mainly consists of volume, height and wall thickness. At the same time, its size design will be one of the key factors affecting its functionality and user experience. When determining the size of an aerosol can, the properties of the aerosol, the usage scenario, user needs, and transportation and storage requirements must be considered comprehensively.

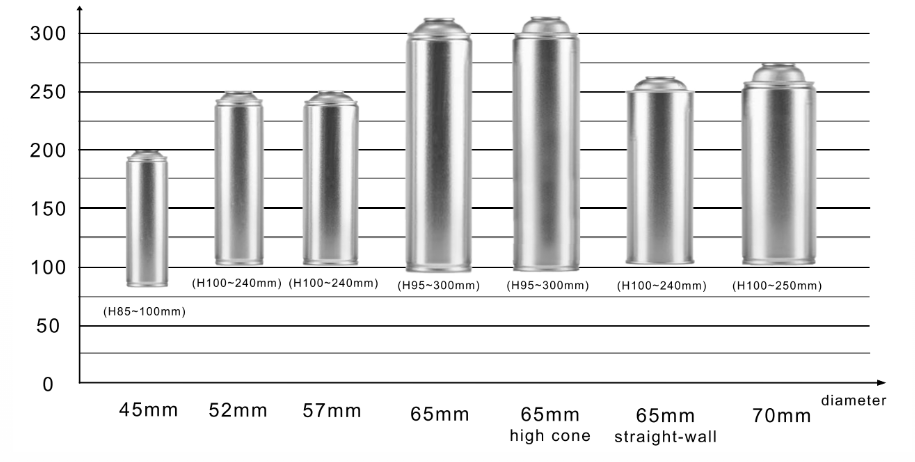

Aerosol can height and diameter

The height and diameter of an aerosol can directly affect its convenience of holding and using. Ogólnie, the height-to-diameter ratio of aerosol cans should be designed to be ergonomic, allowing users to hold and operate them easily. Slender aerosol cans are easy to hold and spray, while shorter and fatter designs may be suitable for products that require larger capacity. In addition, the height and diameter need to take into account the efficiency of transportation and storage to ensure that space can be saved when packaging and displaying.

Aerosol can wall thickness and structural strength

The wall thickness of the aerosol can must be strong enough to withstand the internal pressure and prevent leakage or rupture. The design of the wall thickness not only affects the safety and durability of the aerosol can, but is also directly related to its weight and manufacturing cost. Under the premise of ensuring strength, they will try to optimize the wall thickness to reduce material consumption and production costs. Aluminum and tin are commonly used materials for aerosol can manufacturers because of their good strength and corrosion resistance, which are suitable for manufacturing high-pressure aerosol cans.

Matching of aerosol can nozzles and valves

The size design of the aerosol can also consider the matching of the nozzle and valve. The design of the nozzle and valve needs to be adapted to the size of the can to ensure the spraying effect and user experience. Different aerosol spraying requirements require different sizes of nozzles and valve combinations. Dlatego, when designing the size of the tank, the nozzle and valve factors must be considered to provide users with a better experience.

Aerosol can shape and packaging printing

Aerosol can shape design and packaging printing play a vital role in the overall image and market competitiveness of aerosol products. According to the product characteristics of aerosol merchants, aerosol cans of different shapes are manufactured. Classic cylindrical, palm-held, streamlined design and other cans are common in the market. Some merchants will require manufacturers to print on their aerosol cans. Designers combine product names, ingredient lists, instructions for use, warning signs and manufacturer information with exquisite patterns to express the characteristics of corresponding aerosol products and make the products more attractive in the market.

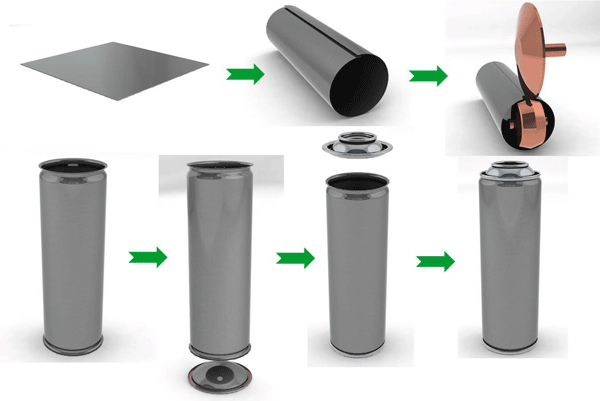

Stamping and stretching

When the material and design of the aerosol can are determined, the third step of the manufacturing process can be started, which is to stamp the metal sheet into the preliminary can shape. This is usually done on a high-pressure punch press, and the sheet is stamped into a circular sheet through a die. Subsequently, the sheet is stretched into the basic shape and height of the can using a stretching process. In this process, it is very important to ensure that the wall thickness of the can is uniform and the surface is smooth.

Welding and forming

If the can consists of multiple parts, they need to be connected by welding. High-frequency welding is commonly used in modern aerosol can manufacturing. This technology can quickly and reliably connect metal sheets to form a solid can body. After forming, the can body needs further trimming to ensure accurate size and shape.

Internal and external coating treatment

The inner surface of the aerosol can is usually coated with a protective coating. The main purpose is to prevent the aerosol from reacting with the metal. The coating treatment is usually carried out on an automated spraying line to ensure that the coating is uniform and defect-free. The outer surface is decoratively coated and printed, including brand logos, instructions for use and other information. These external treatments not only enhance the aesthetics of the product, but also provide additional protection.

Cleaning and testing

After forming and coating, the aerosol can needs to be thoroughly cleaned to remove any residual oil and impurities. The cleaning process usually includes multiple cleaning and drying steps to ensure that the inside and outside of the can body are completely clean. Then it enters the quality inspection link, which includes wall thickness, rozmiar, welding quality and coating integrity. Water will also be added to replace aerosol for sealing test and spray effect test to ensure that each can meets the quality standards

Wniosek

The manufacturing process of aerosol cans is a complex process involving multiple procedures, fine control and strict quality inspection. Through advanced manufacturing technology and automated equipment, manufacturers can produce high-quality aerosol can products to meet market demand and ensure consumer safety and satisfaction. Fanxun has more than 20 years of experience in aerosol can production and has multiple automated aerosol can production lines to help you create your own brand of aerosol products