Aerosol cans are a widely used packaging container. Since its introduction in 1941, it has become more and more popular because of its convenience and wide application. Aerosols are used in many products in the fields of medical, pharmaceutical, cosmetic, chemical and household cleaning.

Aerosol cans are an important part of aerosol products, but not all aerosol cans are suitable for all aerosols. Different types of aerosol cans are suitable for different products and uses.

Once the wrong choice is made, it will directly affect the performance and safety of the product. Vì thế, it is crucial to choose the right can.

Filling of the can: What’s inside is important

The first thing is to understand the product. Is it a liquid that needs to be pushed out of the nozzle with force? Or is it a gas? The nature of the product affects the type of can. Liquids require the can to withstand internal pressure, while gases require similar strength.

Basic structure and knowledge of aerosol cans

Although there are many types of aerosol cans, their basic structure and working principle are the same.

Components of aerosol cans

Mainly composed of three main parts

Can body: The can body is the container for the product and propellant. It is usually made of metal (such as tinplate or aluminum) hoặc nhựa.

Base: The base is the bottom of the can. It is usually made of the same material as the can.

mũ lưỡi trai: The cap is the top of the can. It has two main parts: the valve and the nozzle. Van điều khiển việc phát hành sản phẩm, and the nozzle controls the spray pattern of the product

How Aerosol Cans Work

Aerosol cans work by using pressure to spray the product out of the container. When the valve is pressed, a hole opens to let the propellant out. The propellant pushes the product up into the nozzle. The nozzle atomizes the product into fine droplets or gas.

Types of Aerosol Cans

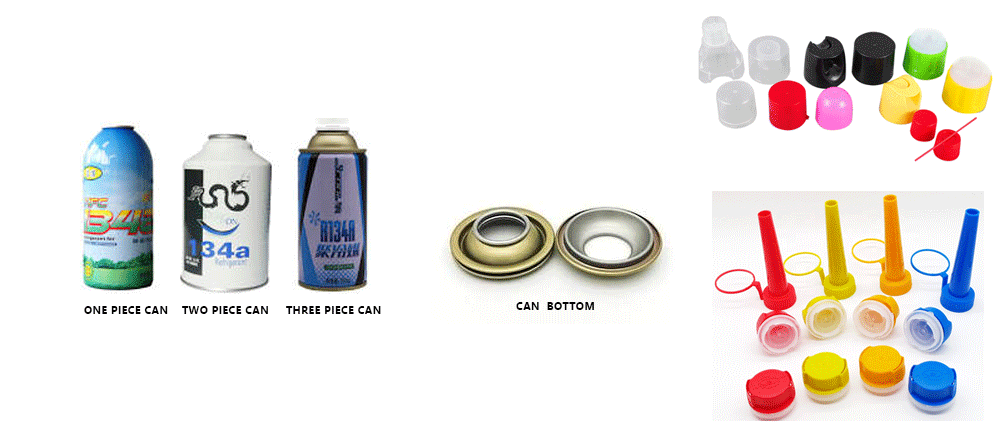

Lon bình xịt have a can body made of one piece, two pieces, and three pieces. There are 3 basic types of aerosol cans on the market: traditional aerosol cans, pumpless aerosol cans, and metered aerosol cans. They can be made of aluminum, thiếc, nhựa, and glass.

Traditional Aerosol Cans

Traditional aerosol cans use liquefied petroleum gas (LPG) or other inert gases as propellants. These cans are suitable for a variety of products, including household cleaners, chăm sóc cá nhân, car care, chemical products, and food.

Pumpless Aerosol Cans

Pumpless aerosol cans do not use propellants. Instead, they use the product’s own pressure to spray the product. These cans are often used for cosmetics and personal care products.

Metered Aerosol Cans

Metered aerosol cans are equipped with a metering valve that releases a specific amount of product. These cans are often used in medical applications.

Choosing the right type of aerosol can is essential to ensure that your product is used safely and effectively. Before making a choice, be sure to consider the specific needs of your aerosol product and application scenario.

Hợp tác với Fanxun: A Reliable Aerosol Can Manufacturer

When it comes to choosing a reliable and suitable aerosol can manufacturer for your packaging needs, partnering with FANXUN is an ideal solution. FANXUN has a reputation for quality, sự đổi mới, and expertise in aerosol can manufacturing. With more than 20 years of manufacturing experience, we can provide customers with a suitable Aerosol có thể solution for their aerosol products. Ngoài ra, a wide range of customized aerosol can options are available to ensure that your aerosol cans meet your brand, product requirements, and packaging preferences. From choosing the right size to incorporating your logo and design elements, FANXUN can customize your aerosol cans to reflect your brand image and enhance the visual appeal of your products, making your products stand out in the market.