Condividi questo prodotto

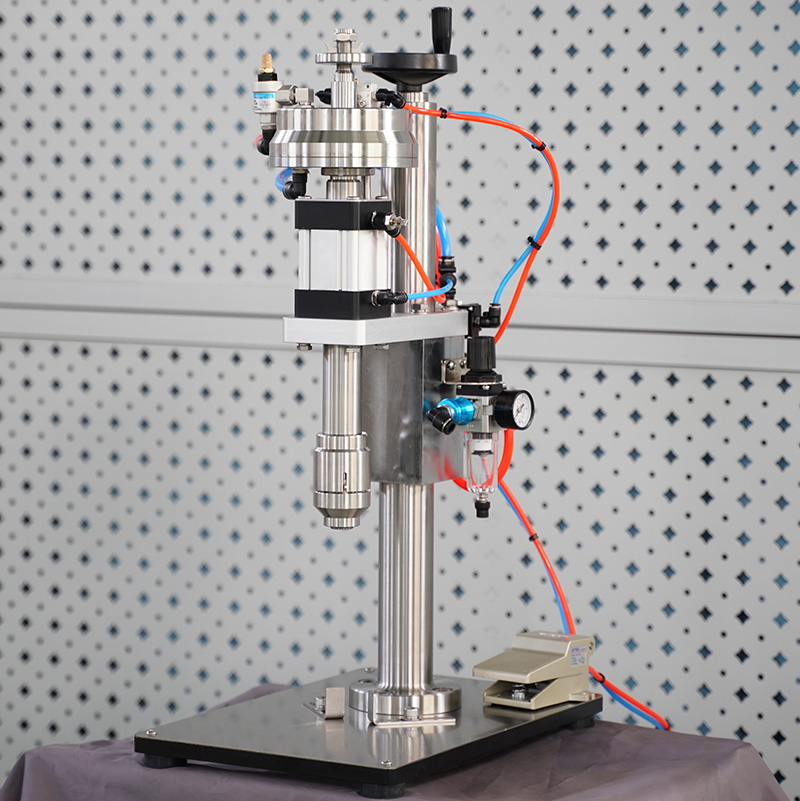

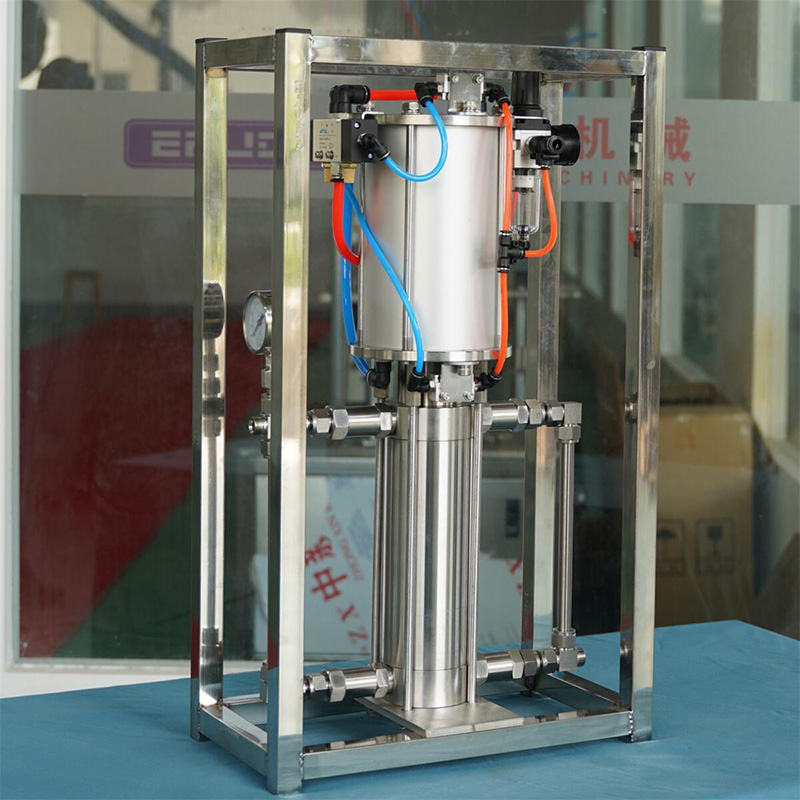

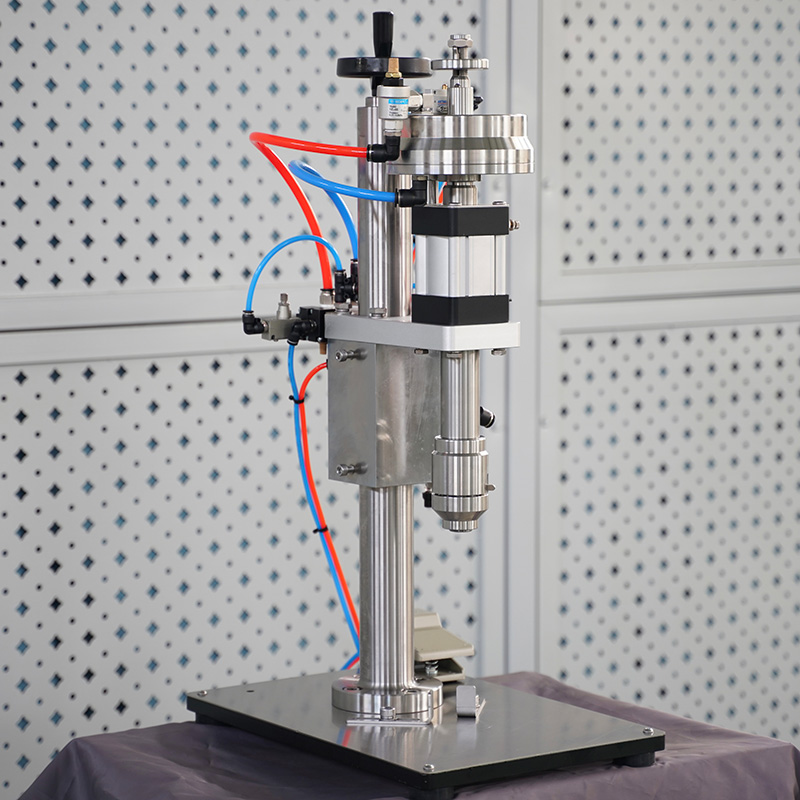

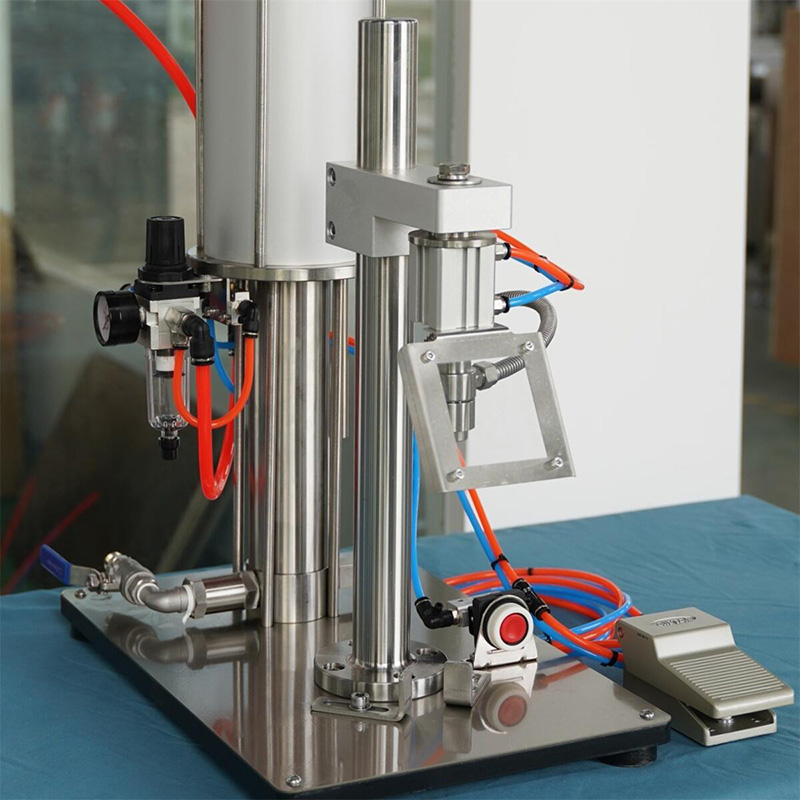

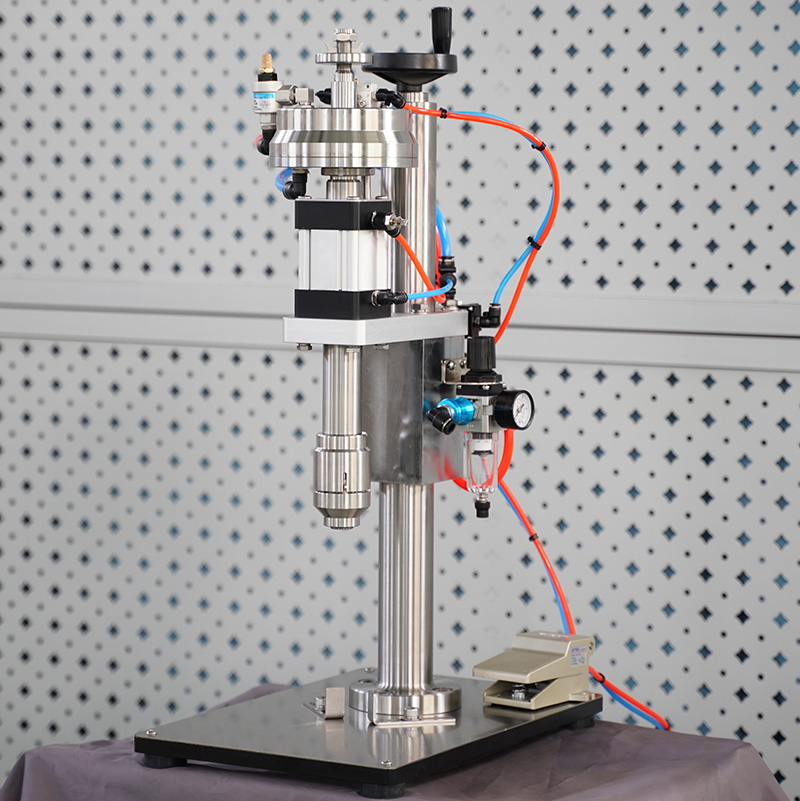

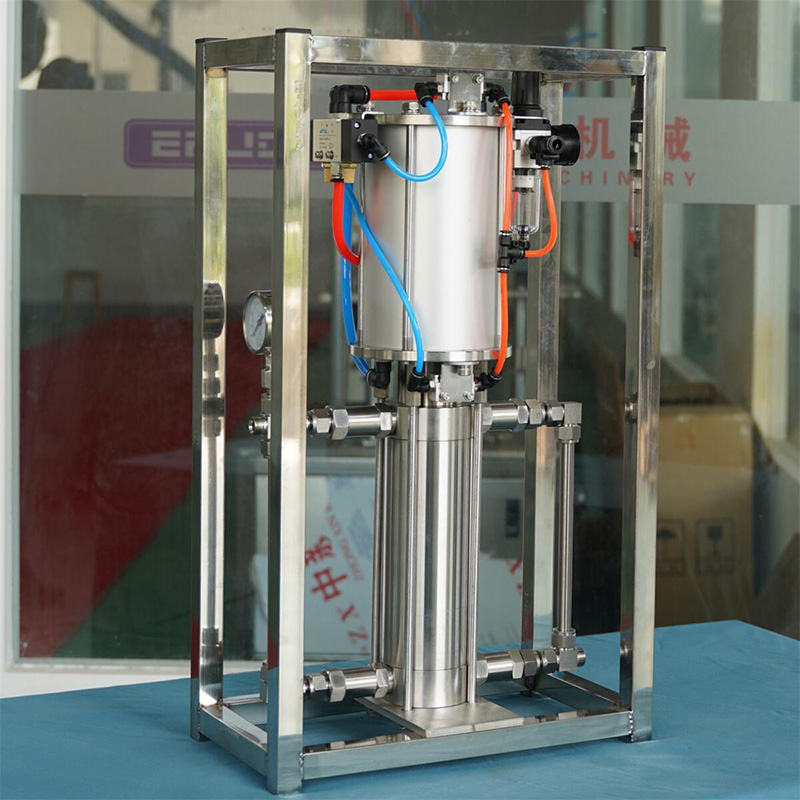

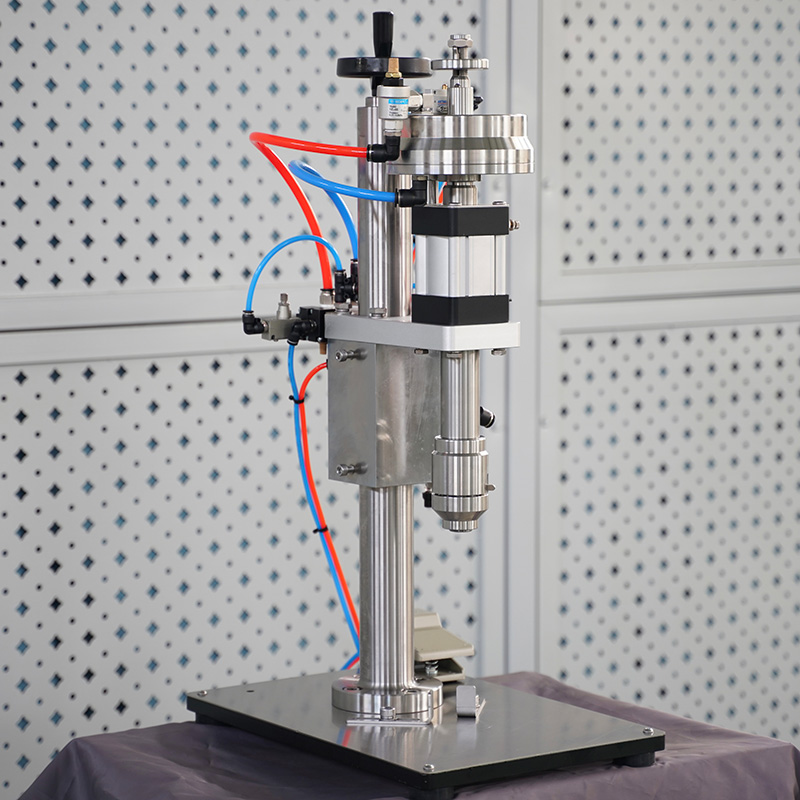

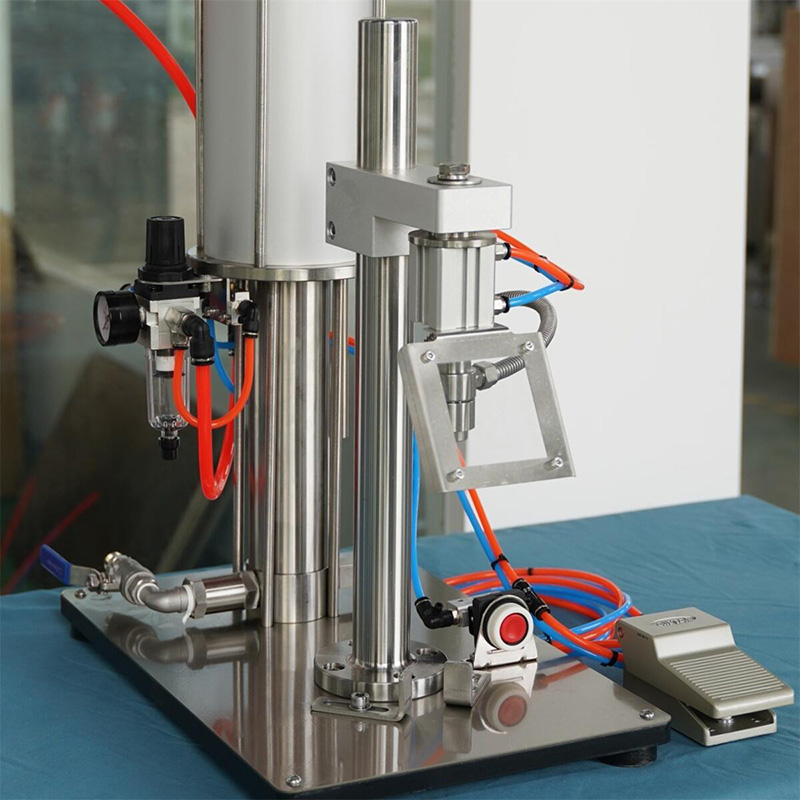

Simple and Efficient Structure

This manual aerosol filling machine is designed with a compact and user-friendly structure, making it ideal for small-scale production environments. The equipment typically includes a manual control valve, precision filling head, manometro, serbatoio di stoccaggio liquido, and a sturdy support bracket. Its intuitive layout allows for straightforward operation, even for users with minimal technical experience, ensuring efficient and reliable performance.

Flexible and Adjustable Operation

Tailored for flexibility, this machine is perfect for laboratory settings or small-batch production lines. Operators can manually adjust both the filling volume and pressure settings to meet specific product requirements. This adaptability makes the equipment suitable for various filling needs, allowing users to switch between different formulations with ease.

Cost-Effective Investment

Compared to automated filling systems, manual aerosol filling machines offer a significantly lower investment cost, making them an ideal choice for start-ups, small businesses, or R&D departments operating on a limited budget. Despite the lower cost, the machine delivers reliable performance and consistent results, providing excellent value for money.

Low Maintenance and Easy Cleaning

Thanks to its simple mechanical design, this machine is not only easy to operate but also easy to maintain. Routine maintenance tasks such as cleaning and part replacement can be performed quickly without the need for specialized tools or technical knowledge. This reduces downtime and helps maintain long-term operational efficiency.

Versatile Application Range

The manual aerosol filling machine supports a wide variety of aerosol product types. It is suitable for filling cosmetics (such as hair sprays and deodorants), household cleaners, industrial lubricants, paint sprays, insecticides, e altro ancora. This versatility makes it an essential tool for businesses across various sectors.

High Filling Accuracy with Skilled Operation

While manually operated, the machine can achieve high filling precision when used by trained personnel. Accurate control over the filling process minimizes product waste and ensures consistent output, making it a reliable option even for high-quality production requirements.

*Tutte le tue informazioni sono rispettate & protetto.