In modern life, the use of aerosol cans has penetrated into all walks of life. These products can accurately release the contents at the moment we press the valve, which is convenient and efficient, and has excellent preservation performance. Behind all this, it is inseparable from the ingenious design of the valve sealing principle of aerosol cans. It is not only the key to ensure product functionality, but also an important technology to ensure consumer safety.

Structure and working principle of aerosol cans

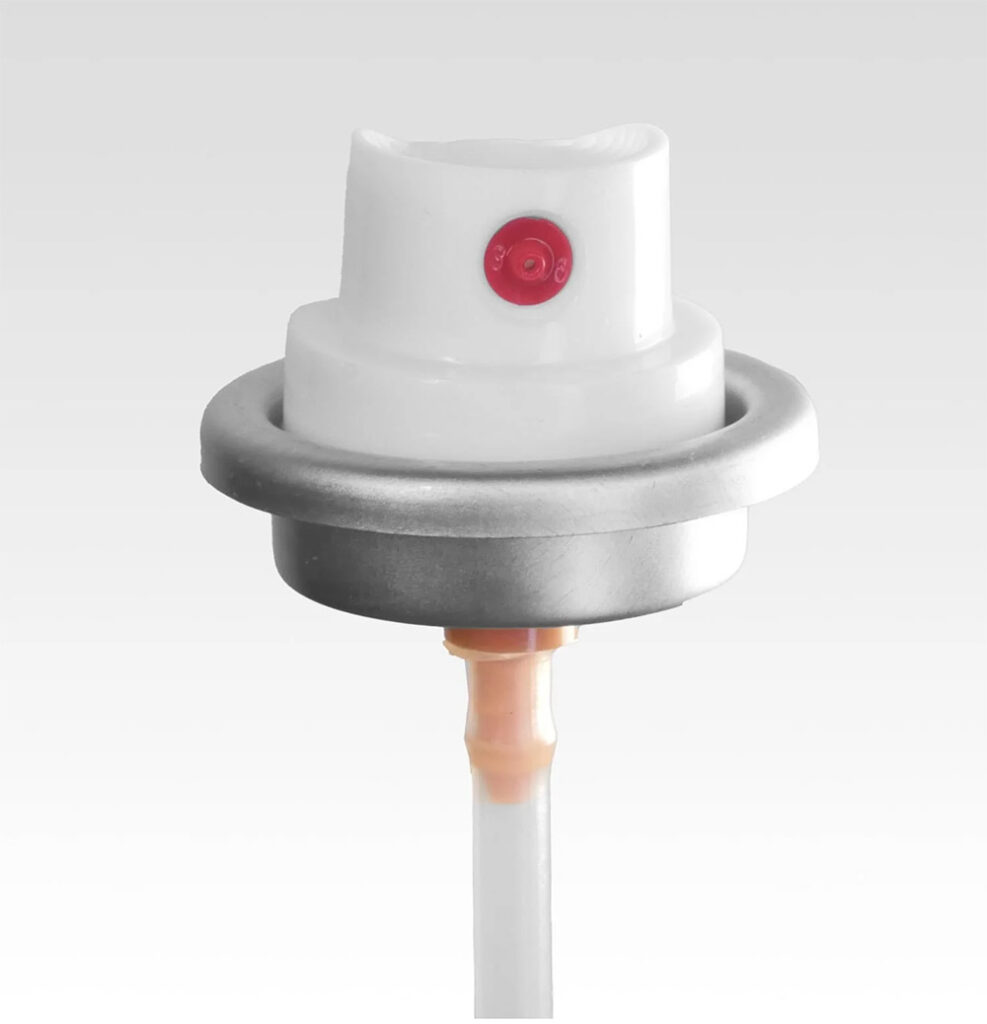

Bombes aérosols are generally composed of a tank body, a valve and a nozzle. One of its core structures is the valve sealing system, which is responsible for effectively isolating the contents of the aerosol can from the external environment to avoid product deterioration or leakage due to external air pressure, humidity and other factors. Specifically, aerosol cans are usually filled with a gas (such as compressed gas or liquefied gas), and the valve controls the release of gas and liquid.

When the user presses the nozzle, the pressure inside the aerosol can quickly pushes the liquid out of the nozzle, and the valve seal ensures the precise spraying of the contents and prevents air and external contaminants from entering the can. In this way, the aerosol can can ensure the continuity and stability of the product and avoid product failure or corruption caused by air entry.

Core technology of valve sealing principle

The design of the valve seal of the aerosol can is very particular. It not only needs to withstand the high pressure in the can, but also ensure that there will be no leakage, blockage and other problems during use. Donc, the material selection, structural design and sealing technology of the valve are all crucial.

Material selection of aerosol can valves

The valves of aerosol cans are generally made of corrosion-resistant and pressure-resistant materials, such as stainless steel or copper alloys, which can effectively resist the pressure of the gas in the can and will not deform or corrode during use. The valve seal design needs to ensure that it can maintain a tight seal under high pressure. Common sealing technologies include O-rings, spring compression and other structures, which can make the valve fit the tank fully when closed to avoid leakage or gas escape.

Efficient sealing ensures safe use

Sealing is one of the keys to the safety of aerosol cans. The sealing of the valve seal directly determines whether the pressure of the aerosol can is stable, whether it can effectively prevent gas leakage and volatilization of the substances in the can. If the sealing is not good, the aerosol can may leak before it is used, and even cause danger. Par exemple, once the gas leaks, it may cause the contents in the tank to lose their effectiveness, and may even cause the aerosol can to explode or spray by mistake during use.

Performance test

To ensure the sealing performance, aerosol can manufacturers usually conduct strict quality control and use multiple testing methods to test the valve seal of each can. Common testing methods include air tightness test, pressure resistance test, etc.. These tests can ensure that each aerosol can maintain the best safety and functionality during use.

Convenience of operation and user experience

The design of the valve seal should not only be able to effectively maintain the seal, but also ensure that the user can get a comfortable feel when pressing the valve, and the spray can be released evenly. Most modern aerosol cans use a spring-type design that is easy to operate. With this design, consumers only need to press the valve lightly to trigger the internal air pressure and release the spray. This design not only reduces the burden on users during operation, but also avoids the problem of complex and laborious operation of traditional aerosol cans.

Technological innovation and future development

With the advancement of science and technology, the sealing technology of aerosol can valves is also constantly innovating. The use of new materials, more sophisticated sealing technology, and intelligent injection control systems will make the functions of aerosol cans more complete. Par exemple, some high-end aerosol cans have begun to use intelligent sensing technology, which can adjust the spray volume according to the strength of the user’s press, greatly improving the user experience.

Résumé

The sealing principle of the aerosol can valve is not only a guarantee of the safety and performance of the aerosol can, but also an important part of the user experience. Avec l'avancement continu de la technologie, we can expect more innovations and breakthroughs in safety, ease of operation, and environmental protection in the future. Behind every spray of an aerosol can, it is the power of technology that ensures our safety and convenience.