Compartilhe este produto

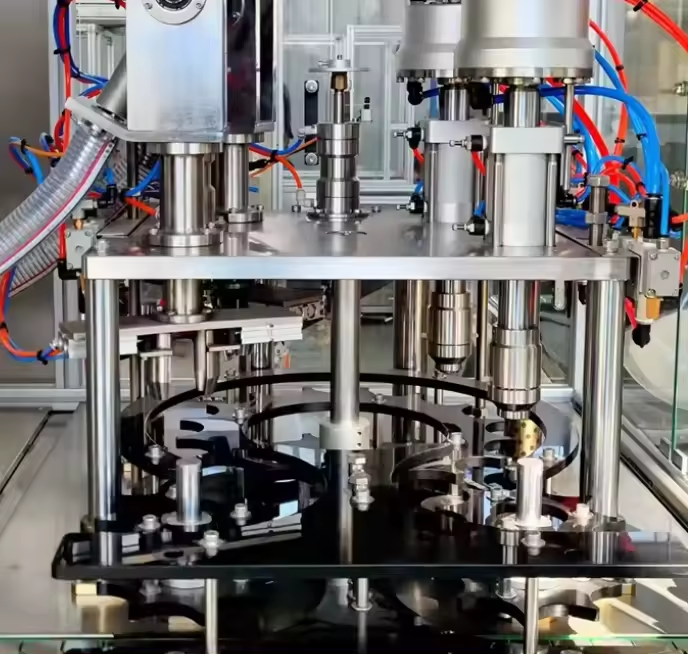

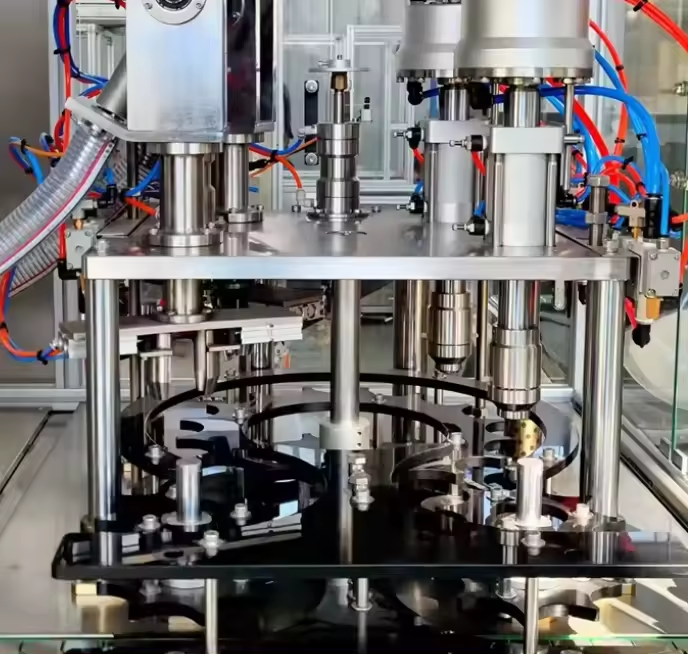

Our semi-automatic aerosol filling machines are designed to meet the production demands of small to medium-sized enterprises that prioritize flexibility, cost-efficiency, and high-quality output. Combining manual and automated features, these machines offer a reliable solution for diverse aerosol product manufacturing needs. Below are the key features and benefits:

1. Flexible Operation

Unlike fully automatic machines, semi-automatic aerosol fillers allow for greater control and customization during the production process. Operators can adjust parameters based on specific product requirements, making the equipment ideal for small-batch or multi-variety production environments. This flexibility is especially valuable when dealing with a wide range of formulas, container sizes, or frequent changeovers.

2. Cost-Effective Solution

Semi-automatic machines offer a more affordable alternative to high-end automated systems without compromising on performance. With a lower initial investment and reduced operational costs, they provide excellent value for small to mid-sized manufacturers seeking to optimize production without incurring heavy capital expenditures.

3. Precision Filling

Despite being semi-automatic, these machines ensure high accuracy and consistency in every fill. They are equipped with precise metering systems and quality control mechanisms to maintain exact filling volumes, reducing waste and ensuring product uniformity across batches.

4. Manutenção fácil

Designed with simplicity in mind, the machine’s structure allows for easy maintenance and quick troubleshooting. Fewer complex components mean fewer breakdowns, less downtime, and lower maintenance costs—helping your production stay efficient and reliable.

5. Compact Design

With a compact footprint, this equipment is ideal for facilities with limited space. Its space-saving design allows seamless integration into existing production lines and is suitable for use in small workshops, laboratories, or pilot-scale environments.

6. Manual-Automatic Integration

This machine requires basic manual involvement, such as positioning cans and initiating the fill cycle, allowing operators to maintain full control over the production process. The hybrid operation mode increases operational awareness while still delivering the benefits of automated filling systems.

7. Versatile and Multi-Functional

Capable of handling various types of aerosol cans and filling materials—including sprays, foams, and liquids—this machine is highly adaptable. It supports different container sizes and propellants, making it suitable for a wide range of industries including cosmetics, automotive, doméstico, farmacêuticos, e mais.

*Todas as suas informações são respeitadas & protegido.