Share this product

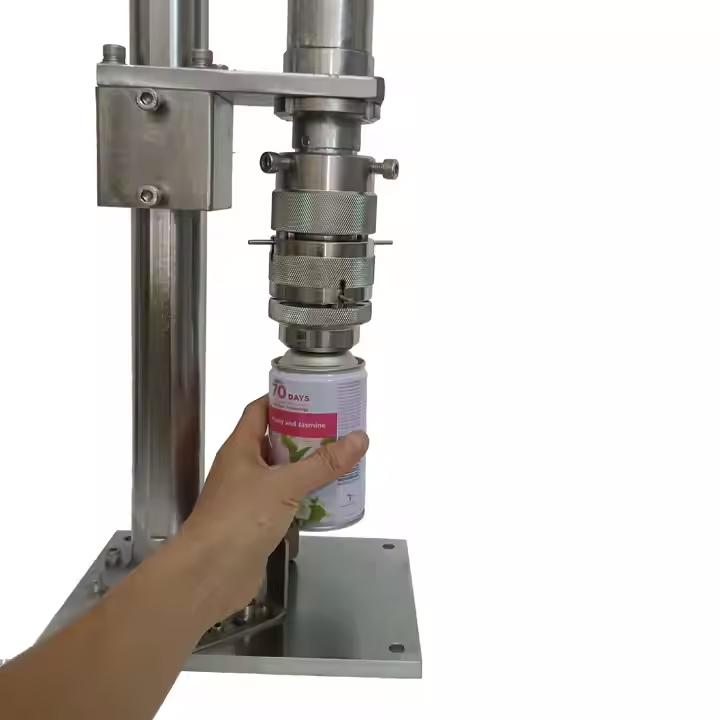

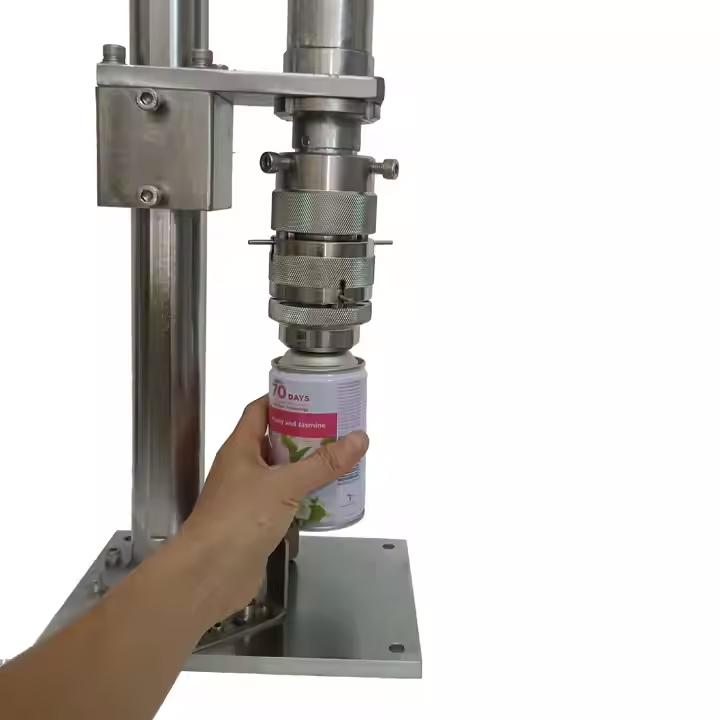

Our manual aerosol can gas filling machine is a compact, easy-to-use solution designed for small batch production, laboratory use, and startups. Combining a streamlined structure with reliable functionality, this equipment enables users to safely and accurately fill aerosol cans with propellants or compressed gases for a variety of spray products.

This manual filling machine is built with a user-friendly design, typically including:

A manual control valve for gas flow regulation

A filling head that securely attaches to the canister

A pressure gauge to monitor filling pressure

A liquid storage tank for gas or propellant

A durable support bracket for stability during operation

Its compact structure and minimal footprint make it ideal for use on workbenches or limited-space production setups.

The machine offers excellent operational flexibility.

Operators can adjust the filling volume and pressure based on the specific requirements of different aerosol products.

Suitable for custom, experimental, or low-volume production, it allows greater control compared to automated systems, making it ideal for R&D labs, pilot production lines, or small businesses.

Compared with fully automated aerosol filling systems, this manual version offers a significantly lower upfront cost, making it perfect for:

Small and medium-sized enterprises (SMEs)

Startups with limited capital

Businesses looking to test product formulations before scaling up

Despite its affordability, the machine delivers consistent performance and professional results.

Thanks to its simple mechanical structure, maintenance is straightforward:

Minimal moving parts mean fewer breakdowns

Easy-to-clean components reduce downtime between production runs

Operators with basic training can handle daily inspections, cleaning, and minor repairs, ensuring operational longevity

This manual aerosol filling machine is compatible with a broad spectrum of products and industries, including:

Cosmetics: Perfumes, deodorants, hair sprays

Household Products: Air fresheners, disinfectant sprays, cleaning agents

Automotive & Industrial: Lubricants, spray paints, rust inhibitors

Others: Insecticides, odor neutralizers, foam products

Its versatility makes it a valuable addition to any small-scale aerosol packaging operation.

Although manually operated, this machine can achieve high filling accuracy in the hands of a skilled operator.

Accurate gas filling reduces product waste

Maintains consistent can pressure and quality

Prevents overfilling, leakage, or safety issues

With proper operation, it ensures repeatable performance and professional-grade packaging results.

If you’re seeking an affordable, flexible, and reliable way to fill aerosol cans for small production volumes or testing environments, our manual aerosol can gas filling machine offers an ideal solution. Its compact design, ease of operation, and broad application scope make it a smart choice for labs, startups, and custom manufacturing needs.

*All your information are respected & protected.