We produce high-quality aerosol cans for the personal care industry, designed for products like deodorants, hair sprays, dry shampoos, and skincare sprays. Our cans combine durability, safety, and sleek design to protect product integrity and enhance user experience. With customizable options and advanced spray technology, we provide reliable packaging solutions for all types of personal care aerosols.

Our personal care aerosol cans are crafted to meet the strict standards of beauty and hygiene products. Whether for body sprays, sunscreens, or styling products, our packaging ensures consistent spray performance, product freshness, and consumer safety. We offer flexible sizes, modern finishes, and eco-friendly options to support innovative brands in the growing personal care market.

The fragrance is diffused through microporous atomization technology, and the airtightness of the tinplate can prevents the fragrance from evaporating prematurely.

Aerosol cans can precisely control the amount of foam or mist styling agent sprayed, providing a long-lasting styling effect.

Mainly used for men's shaving, the amount of foam can be precisely controlled

Utilize the uniform atomization characteristics of the aerosol can to quickly cover the skin surface and enhance the user experience.

High-pressure spray can spray evenly over a large area, avoiding contamination from hand contact, and is suitable for outdoor touch-ups.

For quick touch-ups or creative styling, the chemical-resistant can is compatible with hair dye ingredients.

Quick-drying formula combined with aerosol can for enhanced immediate results

The high-end texture of the metal can is in line with the positioning of the beauty brand.

FANXUN's Aerosol Cans are trusted for automotive care products. Experience precision in every application.

Elevate your brand with FANXUN's Aerosol Cans, ideal for personal care products such as deodorants, hairsprays, and cosmetics.

Perfect for suppliers catering to artistic and DIY markets, providing secure packaging for bulk paint shipments.

Engineered for the highest quality, safety, environmental responsibility, and stability, meeting the stringent demands of the chemical industry.

Customize or private label your aerosol can products with our wide range of options to drive your brand.

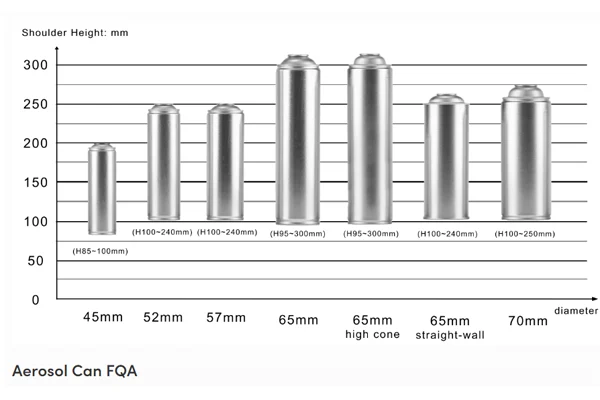

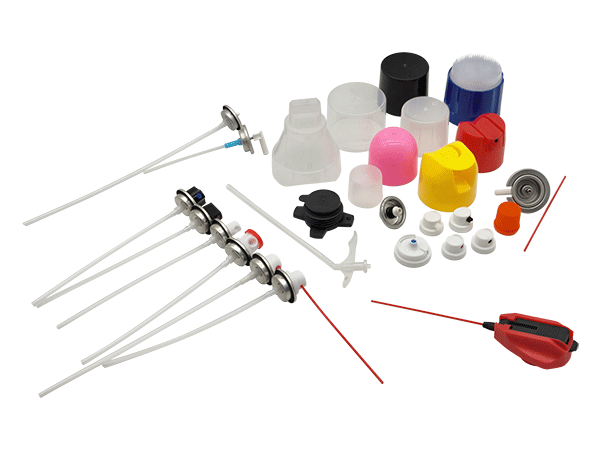

Discover the versatility of FANXUN’s aerosol tin cans, where customization knows no bounds. Choose from a range of shoulder shapes and tailor the sizes to your exact requirements.

Elevate your brand with custom packaging designs. As a reliable aerosol spray bottle manufacturer, our expert design team works closely with you to create artwork that complements your product and captivates your audience.

FANXUN stands as an industrial giant in aerosol can manufacturing. Our advanced factory, fueled by cutting-edge technology, ensures a strong production capacity for efficient and timely deliveries. With a commitment to precision and innovation, we produce top-quality tin cans and offer a robust solution to your tin can packaging needs.

When it comes to manufacturing aerosol cans, aluminum and tin each bring distinct advantages. Let’s delve into the unique features that make these materials stand out:

| Feature | Aerosol Tin Cans | Aluminum Aerosol Cans |

|---|---|---|

| Material | Tinplate | Aluminum |

| Weight | Heavier | Lightweight |

| Durability | Sturdy | Durable |

| Recyclability | Recyclable | Highly recyclable |

| Cost | Cost-effective | Generally higher cost |

| Surface Finish | Classic and versatile | Sleek and modern |

| Customization Options | Varied options available | High |

| Environmental Impact | Recyclable and eco-friendly | Lower carbon footprint |

| Applications | Widely used in various industries including food, beverages, and industrial products | Common in personal care, cosmetics, and pharmaceuticals |

Tin material in aerosol cans provides compatibility assurance, crucial for industries like chemical and automotive care, ensuring safe containment and dispensing of various substances without compromising product integrity or safety.

Aerosol cans are typically made through a combination of metal forming, welding, and assembly processes. Here are key steps involved:

Aerosol cans are designed to reduce environmental impact while maintaining functionality, with manufacturers adopting innovative materials and production processes to make packaging more sustainable.

Made from highly recyclable aluminum or steel. Recycling reduces the need for raw material extraction and lowers energy usage.

Replacement of harmful chlorofluorocarbons (CFCs) with hydrocarbon or compressed air propellants, which have lower global warming potential.

Aerosol cans are crafted with thinner metal walls, reducing material usage while still maintaining strength and durability.

Compatible with eco-friendly formulations, reducing reliance on volatile organic compounds (VOCs).

Use of BPA-free and non-toxic internal coatings to ensure recyclability and reduce health hazards.