We not only have practical packaging, but also pay attention to the display effect of the product appearance. Our car care jars support customized printing, color label design and brand exclusive mold opening services, helping customers improve product recognition and brand professional image. Whether it is OEM orders or personalized small batch customization, we can provide flexible and efficient one-stop services, and are a trusted packaging partner for many car care brands.

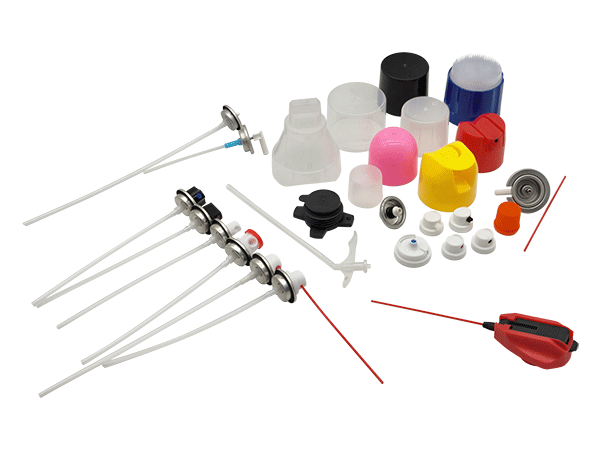

We specialize in the design and manufacturing of packaging cans for automotive care products, offering safe, professional, and durable packaging solutions for a wide range of applications including car cleaners, tire foams, engine bay degreasers, and interior care liquids. Our cans feature excellent sealing performance and strong resistance to chemical corrosion, ensuring product stability during transportation and storage. Available in various sizes, capacities, and dispensing options, our cans are well-suited for spray, foam, and liquid formulations across different usage scenarios.

Enhance fuel efficiency, clean engines, and reduce emissions.

Cleans carbs, removes deposits, restores engine performance.

Penetrates the rust layer, combining the functions of rust prevention and loosening bolts.

Fills minor scratches and temporarily repairs paintwork.

Quickly soften dirt, reduce scratches, suitable for car paint surface cleaning

Dissolves stubborn tar, shellac or resin residues.

For oxidation pollution of brake pad iron filings or industrial dust.

Powerful removal of brake dust, oil stains, some of which contain acidic ingredients

Removes stains from seats and ceilings, some contain antibacterial ingredients.

The spray penetrates deep into the air duct to sterilize and deodorize.

Cleans and forms an anti-static protective layer at the same time.

Contains silica or polyurethane to form a hydrophobic protective layer.

Reflect sunlight and delay the aging of car paint.

Restores rubber gloss, some contain anti-UV ingredients.

Prevent door and sunroof rubber strips from aging and cracking.

Elastomeric coating for stone chip resistance and corrosion resistance

Low viscosity lubrication reduces abnormal noise.

Thaw frozen car locks and lubricate them to prevent rust.

Remove dust and lubricate the tracks.

Rapidly evaporates to clean engine sensors and circuit connectors

Temporary repair of small puncture holes requires use with inflation

Solidifies at high temperatures and blocks tiny leaks in the cooling system.

Repair cracks by vacuum infusing resin.

Spray on car windows to prevent ice formation.

Used in rearview mirrors or camera lenses to enhance visibility in rainy days.

Simulate the effect of an ozone generator to decompose smoke and moldy odors

Contains quaternary ammonium salt or hypochlorous acid ingredients to kill mold

Temporarily change the color of the wheel or body, no residue left after tearing off

Used for vehicle body marking at night to enhance safety.

Remove the oxide layer of metal parts such as exhaust tail throat

Repair yellowed lampshade and restore light transmittance

FANXUN's Aerosol Cans are trusted for automotive care products. Experience precision in every application.

Elevate your brand with FANXUN's Aerosol Cans, ideal for personal care products such as deodorants, hairsprays, and cosmetics.

Perfect for suppliers catering to artistic and DIY markets, providing secure packaging for bulk paint shipments.

Engineered for the highest quality, safety, environmental responsibility, and stability, meeting the stringent demands of the chemical industry.

Customize or private label your aerosol can products with our wide range of options to drive your brand.

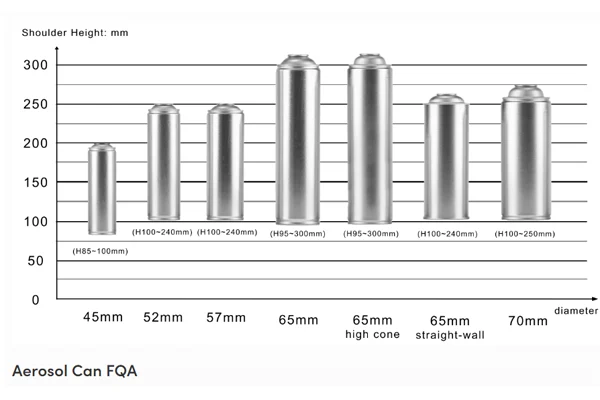

Discover the versatility of FANXUN’s aerosol tin cans, where customization knows no bounds. Choose from a range of shoulder shapes and tailor the sizes to your exact requirements.

Elevate your brand with custom packaging designs. As a reliable aerosol spray bottle manufacturer, our expert design team works closely with you to create artwork that complements your product and captivates your audience.

FANXUN stands as an industrial giant in aerosol can manufacturing. Our advanced factory, fueled by cutting-edge technology, ensures a strong production capacity for efficient and timely deliveries. With a commitment to precision and innovation, we produce top-quality tin cans and offer a robust solution to your tin can packaging needs.

When it comes to manufacturing aerosol cans, aluminum and tin each bring distinct advantages. Let’s delve into the unique features that make these materials stand out:

| Feature | Aerosol Tin Cans | Aluminum Aerosol Cans |

|---|---|---|

| Material | Tinplate | Aluminum |

| Weight | Heavier | Lightweight |

| Durability | Sturdy | Durable |

| Recyclability | Recyclable | Highly recyclable |

| Cost | Cost-effective | Generally higher cost |

| Surface Finish | Classic and versatile | Sleek and modern |

| Customization Options | Varied options available | High |

| Environmental Impact | Recyclable and eco-friendly | Lower carbon footprint |

| Applications | Widely used in various industries including food, beverages, and industrial products | Common in personal care, cosmetics, and pharmaceuticals |

Tin material in aerosol cans provides compatibility assurance, crucial for industries like chemical and automotive care, ensuring safe containment and dispensing of various substances without compromising product integrity or safety.

Aerosol cans are typically made through a combination of metal forming, welding, and assembly processes. Here are key steps involved:

Aerosol cans are designed to reduce environmental impact while maintaining functionality, with manufacturers adopting innovative materials and production processes to make packaging more sustainable.

Made from highly recyclable aluminum or steel. Recycling reduces the need for raw material extraction and lowers energy usage.

Replacement of harmful chlorofluorocarbons (CFCs) with hydrocarbon or compressed air propellants, which have lower global warming potential.

Aerosol cans are crafted with thinner metal walls, reducing material usage while still maintaining strength and durability.

Compatible with eco-friendly formulations, reducing reliance on volatile organic compounds (VOCs).

Use of BPA-free and non-toxic internal coatings to ensure recyclability and reduce health hazards.