Share this product

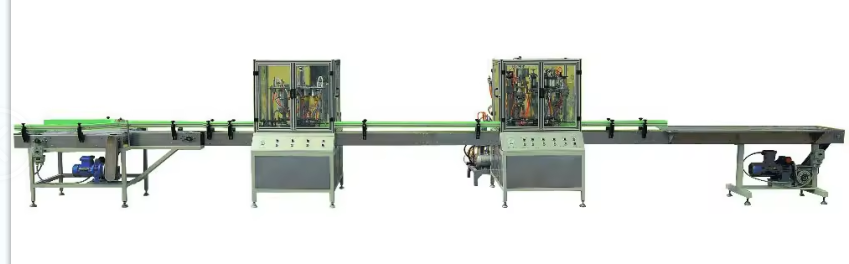

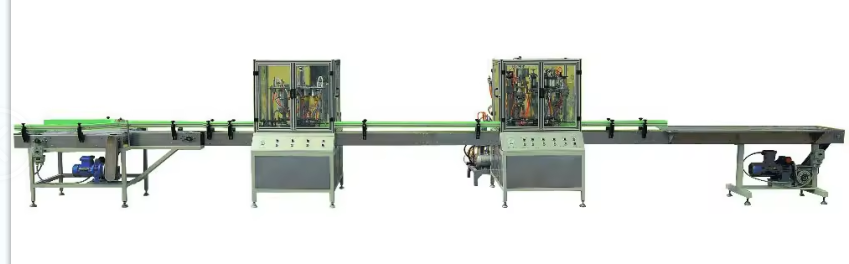

The Automatic Aerosol Filling Machine is a state-of-the-art equipment designed for the efficient and precise filling of liquids, gases, or powders into aerosol cans. Engineered for modern industrial applications, this machine is ideal for manufacturers seeking high-speed, high-volume production without compromising on quality or safety. Below are its core features:

Equipped with advanced automation technology, the machine is capable of completing the entire aerosol filling process swiftly and accurately. Its high production speed makes it especially suitable for large-scale manufacturing operations across industries such as personal care, automotive, geneesmiddelen, and household chemicals.

The machine is integrated with a high-precision metering system that ensures uniform and consistent filling in every aerosol can. With minimal deviation in filling volume, it helps maintain product quality and reduces material wastage.

Designed to handle a variety of aerosol formats, the machine is compatible with different can sizes and types of filling substances—including liquids, compressed gases, and fine powders. This versatility makes it a reliable choice for manufacturers with diverse product lines.

Incorporating premium-grade components and a sophisticated control system, the machine delivers excellent operational stability. Even under continuous, high-load conditions, it maintains long-term reliability, reducing downtime and maintenance costs.

The equipment features an intuitive and ergonomic human-machine interface (HMI) for easy operation. The simplified control panel and interface design reduce the learning curve, allowing operators with minimal technical training to manage the system efficiently. Maintenance and troubleshooting are also streamlined for user convenience.

Safety is a top priority in the design of this aerosol filling machine. It is equipped with comprehensive protection mechanisms such as explosion-proof components, anti-static systems, and emergency stop functions. These features help prevent accidents and ensure safe operation, particularly when working with flammable or pressurized substances.

The machine is built to meet stringent environmental protection standards. It minimizes emissions, reduces raw material loss, and incorporates waste recycling systems to promote sustainable manufacturing practices. This not only protects the environment but also improves cost-efficiency in the long run.

Integrated with advanced automation systems such as PLC (Programmable Logic Controller) or DCS (Distributed Control System), the machine supports real-time monitoring, diagnostics, and automatic control of the filling process. This level of intelligent control improves production traceability, optimizes workflow, and enhances overall operational efficiency.

*Al uw gegevens worden gerespecteerd & beschermd.