Aerosol cans have become a ubiquitous commodity in our daily lives. From cleaning products to personal care products, these portable containers have revolutionized the way we dispense and use various substances. But have you ever wondered how an aerosol can exerts its spray effect?

It mainly relies on its aerosol can valve to play its role. It releases the aerosol liquid inside the can or bottle, allowing us to spray and atomize it easily.

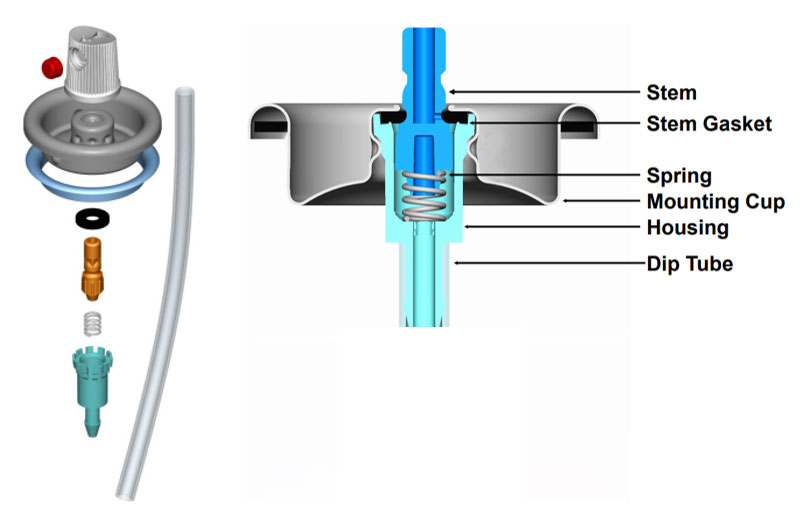

The technology behind aerosol can valves is a combination of physics and engineering. Through a range of accessories, including dip tubes, stems and actuators, valves control the flow of product and prevent leaks when not in use. And the aerosol can valve provides a precise and even spray pattern

The history of aerosol can valves

~ 안에 1926, Norwegian engineer Erik Rotheim patented the first aerosol can, which combined a gas propellant and a valve system to distribute the aerosol liquid.

In the 1940s, the introduction of “press-fit” valves made it easier to attach the valve to the tank, thereby increasing the overall efficiency of the system. As technology continued to evolve, so did valves, with innovations such as the metering valve of the 1950s, which allowed for precise and metered dispensing.

How an aerosol valve works

When we use an 에어로졸 캔, pressing the valve may feel like a simple accessory, but they are actually the result of careful engineering and precise design. The valve is made up of multiple parts that work together to control the amount of product and prevent leaks when not in use.

One of the key components is the dip tube, which extends from the valve into the tank and to the bottom of the vessel. When the valve is depressed, the dip tube allows the propellant to push the product up and out of the tank. This ensures product is dispensed from the tank in a consistent and controlled manner.

The valve stem is another important part of the system. When the actuator on top of the valve is pressed, it activates the valve stem, which opens the valve and releases the product. When not in use, the valve stem also acts as a seal to prevent the contents from leaking or evaporating.

Now do you still think that the aerosol valve is a very simple accessory?

Aerosol can valve advantages

It mainly offers controlled dispersion with multiple advantages. One of the main advantages is the ability to provide a precise and uniform spray pattern. This is especially important in applications such as paints or insecticides, where even distribution is crucial for best results.

또한, the aerosol can valve adjusts the spray pattern, giving users the flexibility to choose between a fine mist, a broad spray, or a concentrated spray. This versatility makes aerosol cans suitable for a variety of products and applications, from hair products to automotive lubricants.

Another advantage of controlled dispersion is reduced waste. With an aerosol can, only the required amount of product is dispensed, minimizing the risk of overuse or spillage. Not only does this save consumers money, it also reduces environmental impact by minimizing product waste.

Applications of aerosol can valves

Aerosol can valves are used in various industries. They are commonly found in industries such as automotive, home cleaning, personal care and food packaging.

Automotive industry: Aerosol cans are used for touch-ups, lubricants and rust inhibitors.

Household Cleaning: They are used in air fresheners, furniture polishes and carpet cleaners.

Personal care industry: Aerosol cans are used in deodorants, hair sprays and shaving foams.

Food Industry: Cooking spray, whipped cream dispenser, and cooking oil spray are just a few examples of how aerosol cans can make food preparation and presentation easier and more convenient.

Impact of aerosol can valves on the environment

While aerosol cans have been criticized for their environmental impact in the past, advances in valve technology have helped alleviate some of those concerns. One of the major environmental concerns associated with aerosol cans is the use of ozone-depleting propellants such as chlorofluorocarbons (CFC) and hydrochlorofluorocarbons (HCFCs). 하지만, due to international regulations and industry efforts, the use of these harmful propellants has been phased out.

오늘, aerosol cans primarily use hydrofluorocarbons (HFCs) or carbon dioxide (CO2) as propellants, which have less impact on the ozone layer. 또한, the controlled dispersion provided by aerosol can valves helps minimize product waste, thereby reducing the overall environmental footprint.

Partner with FANXUN: Reliable aerosol can valve supplier

When it comes to choosing a reliable aerosol can supplier for your aerosol packaging needs, partnering with FANXUN may be the ideal solution. With a reputation for quality, innovation and expertise in aerosol can and accessories manufacturing, FANXUN offers a range of products and services to meet your specific requirements.

Summarize

This article introduces the history, applications, advantages and environmental impact of aerosol valves. More information about related products can be found in our product catalog, or contact our staff