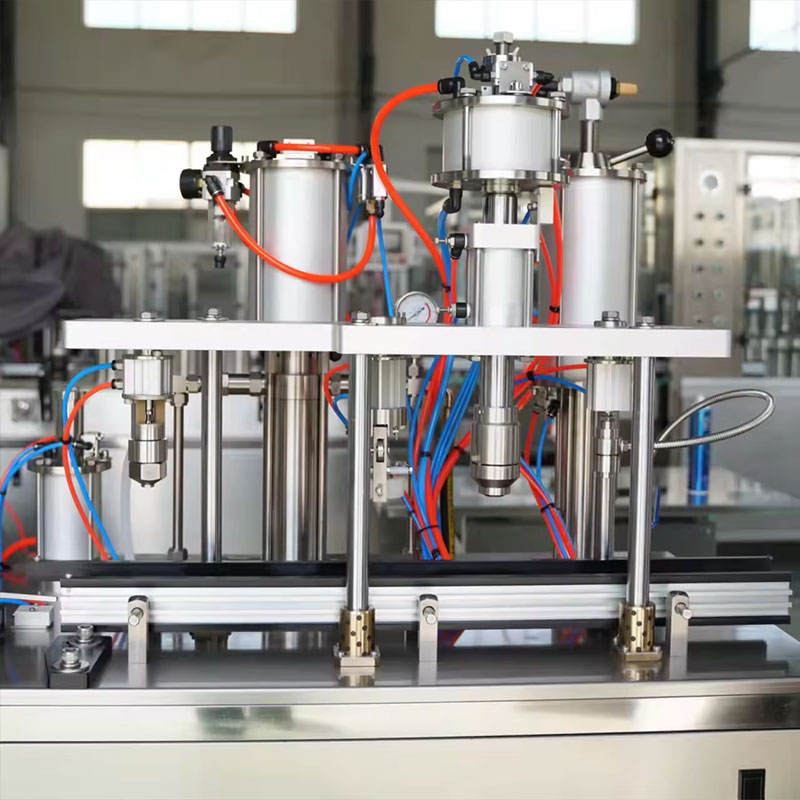

| 製品名 | 半自動エアロゾル充填機 | |

|---|---|---|

| エアロゾル充填目的 | カーケアスプレー /ヘアスプレー /スプレースノー / エアロゾルブタンガス/スプレーペイント/エアフレッシュナー | |

| 原産地 | 広東, 中国 | |

| 機械容量 | 2000 1時間あたりのボトル, 1000 1時間あたりのボトル | |

| アプリケーション | 飲み物, 化学物質, 食べ物 | |

| パッケージングタイプ | ボトル, 缶 | |

| 製品の利点 | 正確な詰め物, 簡単な操作,簡単なメンテナンスなど. | |

| ブランド名 | fanxun | |

| 自動化の程度 | 半自動 | |

| 消費電力 | 1HP | |

1. Easy to Operate

The machine features a user-friendly, semi-automatic design that simplifies operation. Operators can quickly become proficient with minimal training, making it ideal for manufacturers looking to optimize labor resources without compromising on quality.

2. High Filling Efficiency

With its high-speed filling mechanism, the machine is capable of handling large volumes of aerosol paint products efficiently. This significantly boosts productivity and shortens production cycles, helping businesses meet tight deadlines and scale up operations.

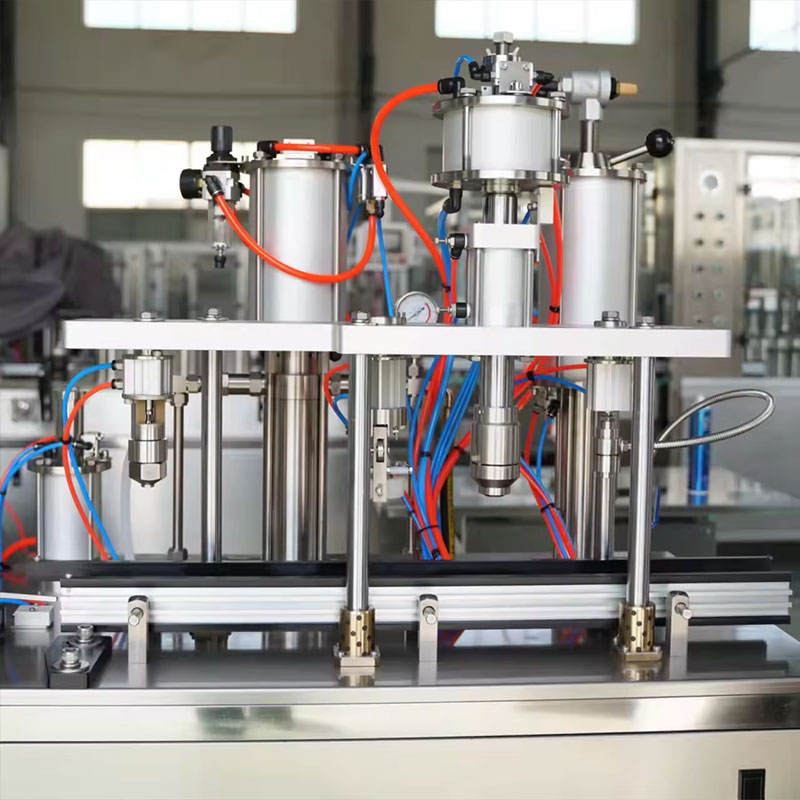

3. Precision Metering System

Equipped with an advanced metering system, the machine ensures each can is filled with a consistent and precise amount of paint. This reduces material waste, minimizes production errors, and improves the overall yield of qualified products.

4. Versatile Compatibility

The equipment is compatible with a wide range of aerosol can sizes and types. This versatility allows manufacturers to easily switch between different product lines and packaging formats, meeting the demands of a diverse and ever-changing market.

5. Superior Safety and Reliability

Built to comply with industrial safety standards, the machine is equipped with explosion-proof components and anti-static protection to ensure safe operation, especially when handling flammable or volatile substances like aerosol paints.

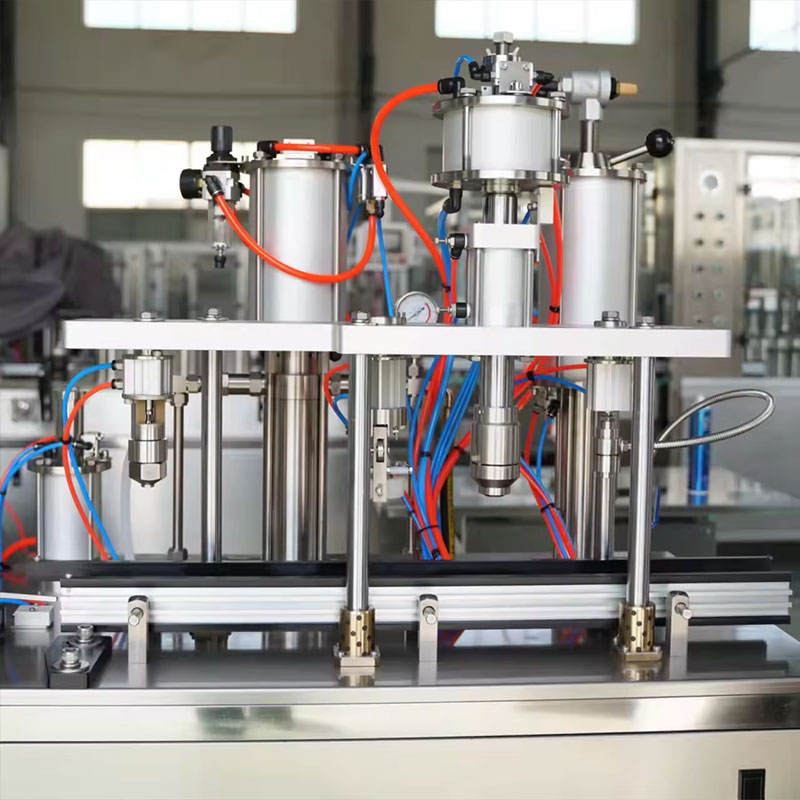

6. Compact and Space-Saving Design

With its compact footprint and ergonomic layout, the machine fits easily into various production environments, including workshops with limited space. Its thoughtful structural design promotes organized workflow and maximized use of available space.

7. Easy Maintenance and Cleaning

The machine’s design prioritizes ease of maintenance, allowing for quick cleaning and part replacement. This reduces downtime, ensures hygienic production conditions, and extends the overall service life of the equipment.

*あなたの情報はすべて尊重されます & 保護されています.