With the diversification of modern consumer demand, エアゾール缶, as a convenient and efficient packaging form, have been widely used in various products in daily life, 化粧品など, 洗剤, food sprays, 等. The valve structure, one of the core components of the aerosol can, plays a vital role in the functionality, stability and safety of the aerosol can. It not only determines the spray effect of the aerosol can, but also affects the user experience

The basis of the aerosol can valve structure

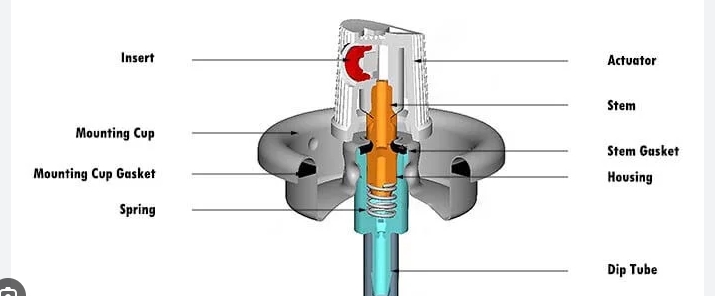

The main function of the aerosol can valve is to release the liquid, gas or mixture in the can to the outside through the action of external pressure. 一般的に言えば, the aerosol can valve consists of components such as valve body, valve core, spring and nozzle. Each component is precisely matched to ensure that the aerosol can can work stably under different conditions of use.

The valve body is the outer shell of the aerosol can valve, usually made of metal or plastic materials, with sufficient strength and pressure resistance to withstand the pressure of the internal gas.

The valve core is the core part of the valve, responsible for controlling the flow of gas or liquid. The valve core is usually designed with a sealing structure to ensure that the aerosol can does not leak when not in use.

The spring is used to provide a certain reaction force to ensure that the valve can open quickly when pressed, release gas or liquid, and can quickly return to its original position after pressing.

The nozzle determines the spraying method and effect of the aerosol can, such as the fineness of the atomization and the spraying distance, which affects the user’s experience.

Application requirements in multiple fields

The innovation of the valve structure of the aerosol can not only improves the functionality of the product, but also expands its application space in different industries. Nowadays, the aerosol can valve is no longer limited to the field of daily consumer goods. Its application range has covered multiple industries, showing great market potential.

Cosmetics industry

The valve structure of the aerosol can has brought revolutionary changes to the cosmetics industry. Whether it is facial spray, body lotion, hair care products or perfume, aerosol cans can be used for more delicate spraying to ensure that the product can evenly cover the skin or hair, and enhance the comfort and use experience of the product. In particular, some high-end brands pay more attention to the design and innovation of valves to enhance the professionalism and high-end sense of the product.

Pharmaceutical industry

The application of aerosol cans in the pharmaceutical field is gradually increasing, especially in the distribution of spray-type drugs. Through the precise control of the aerosol can valve, the drug can enter the respiratory tract or skin directly in an atomized state to ensure the rapid absorption of the drug effect. For example, nebulizer inhalers, allergy drugs, 等, all rely on advanced aerosol can valve technology to ensure the treatment effect.

Food industry

Aerosol cans are also increasingly used in the food field, especially in spray-type cooking oils, condiments and other products, where aerosol can valves play an important role. Through precise spraying, consumers can spray oils or seasonings more evenly, 無駄を減らす, and improve the convenience and health of cooking.

Manufacturing process and quality assurance

With the increasing complexity of valve structure technology, the manufacturing process requirements for aerosol valve manufacturers are also getting higher and higher. Precision machining, automated production and the use of high-quality materials have become the key to ensuring the quality of aerosol can valves. In order to ensure that the valve can maintain stability during long-term use, manufacturers have been striving for excellence in material selection, production process and other aspects.

Material selection: Modern aerosol can valves use high-performance metal and plastic materials that can remain stable for a long time under high pressure. Some manufacturers also use corrosion-resistant materials to ensure that the valve is not damaged when chemicals or drugs are sprayed.

Automated production: By introducing automated production lines, manufacturers can improve production efficiency and product consistency, ensuring that every valve meets high quality standards. This is essential to improving the overall performance and market competitiveness of aerosol cans.

In Summary

The innovation of aerosol can valve structure is not only a symbol of technological progress, but also an important driving force for the development of the consumer goods industry. With the continuous breakthrough of technology and the diversification of market demand, the future of aerosol can valves is full of opportunities and challenges. Whether in terms of product function, intelligent control, or environmental protection design, aerosol can valves will continue to play an important role and become an important force in promoting industry progress.