Ever wondered how your favorite spray can delivers a perfect mist? Welcome to the fascinating world of aerosol packaging! This guide will take you through the ins and outs of aerosol containers, exploring their components, manufacturing processes, and the many benefits they offer. Whether you’re a curious consumer or a budding entrepreneur looking into custom aerosol packaging, you’re in the right place!

What is Aerosol Packaging?

Aerosol packaging is a clever way to store and dispense various products using pressurized containers. Think of it as a magic can that transforms liquids into a fine mist or foam. From household cleaners to personal care products, aerosol packaging makes application easy and efficient. But what exactly goes into creating these convenient containers?

Components of Aerosol Packaging

1. The Can

Aerosol cans are typically made from metals like tin, aluminum or steel. These materials are chosen for their durability and ability to withstand pressure. Imagine holding a soda can; it’s sturdy and can handle the fizz inside—similar principles apply to aerosol packaging! Some companies are even experimenting with eco-friendly materials to reduce their carbon footprint.

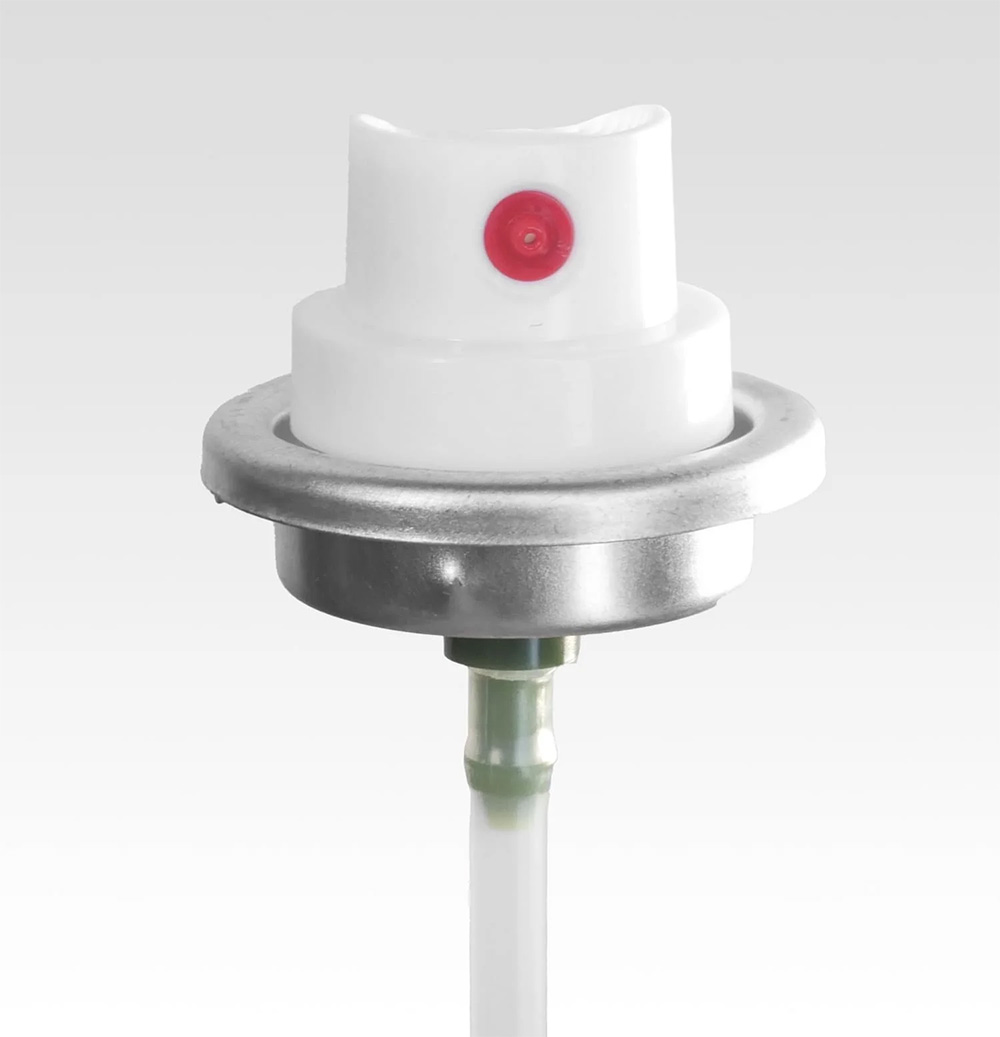

2. The Valve System

The valve system is where the magic happens. Different types of aerosol valves control how the product is dispensed. For example, some valves allow for a fine mist, while others release a heavier foam. This variety ensures that products are delivered in the way that best suits their purpose, whether it’s for styling your hair or spraying cleaner on a surface.

The functionality of the valve is crucial; it ensures a consistent spray and prevents leaks. Think of it like the nozzle on a garden hose—without the right valve, you’d end up with a mess instead of a neat spray. The right valve makes using aerosol packaging container user-friendly and efficient.

Aerosol Can Manufacturing Process

Step 1: Aerosol Can Formation

The journey of aerosol can packaging begins with forming the can itself. The metal is cut and shaped into cylindrical forms, ready to be transformed into the familiar aerosol containers we know. This part of the process requires precision, as even a small flaw can lead to issues later.

Step 2: Aerosol Can Filling Process

Once the cans are formed, they undergo the filling process. Here, manufacturers fill the aerosol cans with the intended product by aerosol filling machines, whether it’s a household cleaner or a personal care item. This stage is critical; filling aerosol cans requires careful monitoring to ensure that each container is filled to the correct level and sealed properly.

Step 3: Quality Control Measures

Quality control measures are essential at every step of the manufacturing process. From testing the strength of the can to ensuring the valve functions correctly, tin can manufacturers take great care to deliver reliable products. After all, no one wants an aerosol can that malfunctions mid-use!

Types of Aerosol Products

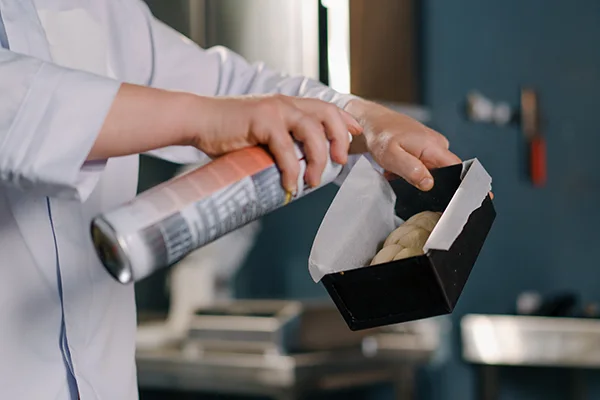

Household Cleaners

Household cleaners are one of the most common uses for aerosol packaging. These products make cleaning quick and easy, allowing for efficient application on various surfaces. Just a few sprays can cover a large area, saving time and effort.

- Surface cleaners

- Disinfectants

- Air fresheners

- Fabric refreshers

Personal Care Items

Personal care products like deodorants, hair sprays, and shaving creams also frequently utilize aerosol packaging. These items benefit from the fine mist application, ensuring an even distribution and a pleasant user experience.

- Deodorants

- Hair sprays

- Shaving creams

- Perfumes

Automotive Products

Aerosol packaging isn’t just for the home; it’s also used in the automotive industry. From tire cleaners to lubricants, aerosol containers make it simple to apply these products precisely where needed, enhancing usability for car enthusiasts.

- Tire cleaners

- Engine degreasers

- Lubricants

- Spray paints

Advantages of Aerosol Packaging

In this chapter, we’ll explore the numerous benefits of aerosol packaging, showcasing why aerosol containers are not just functional but also a smart choice for consumers and manufacturers alike.

Convenience and Portability

One of the standout benefits of aerosol packaging is its convenience. These containers are easy to carry, making them perfect for on-the-go lifestyles. Imagine tossing a travel-sized deodorant in your bag without worrying about spills—pure bliss!

Dispersion Efficiency

Aerosol packaging offers exceptional dispersion efficiency. The pressurized system delivers products evenly and consistently, ensuring you get the right amount every time. No more fumbling with pumps or spills; just a quick spray and you’re good to go.

Safety and Protection

Safety is a significant advantage, too. Aerosol containers are designed to protect their contents from contaminants, ensuring that the product remains effective and safe to use. This is especially crucial for items like pharmaceuticals and cleaners.

Versatility and Adaptability

Aerosol packaging is incredibly versatile, able to accommodate a wide range of products. Whether it’s a thick foam or a fine mist, the technology can adapt to various formulations, making it a go-to choice for many industries.

Eco-Friendly Material

With growing environmental concerns, many manufacturers are looking into eco-friendly materials for aerosol containers. This shift not only benefits the planet but also appeals to environmentally conscious consumers. Sustainable packaging is becoming a key player in product differentiation!

Conclusion

Aerosol packaging is more than just a convenient way to dispense products; it’s a blend of technology, efficiency, and safety. Understanding its components, manufacturing processes, and benefits can help you appreciate the little canister that makes your life easier. Whether you’re using a household cleaner or a personal care product, knowing how aerosol packaging works can enhance your experience and awareness as a consumer.

Common Questions About Aerosol Packaging

- What types of products can be packaged in aerosol cans? Aerosol cans can package a variety of products, including household cleaners, personal care items, automotive products, and more.

- How should aerosol cans be disposed of? Aerosol cans should be disposed of according to local regulations. Many areas have specific guidelines for recycling or hazardous waste.

- Are aerosol cans safe to use? Yes, aerosol cans are safe when used as directed. Always read the label and follow safety instructions to ensure proper use.

- What are the environmental impacts of aerosol packaging? The environmental impacts can vary, but concerns include the use of propellants and materials. Many manufacturers are moving toward eco-friendly options to mitigate these effects.

- How has aerosol packaging evolved over time? Aerosol packaging has evolved significantly, with advancements in materials and technology leading to safer, more efficient, and eco-friendly designs.