Few methods are as convenient and effective as aerosol filling in packaging industry. Whether it’s that favorite hair spray you can’t live without or a can of spray paint for your latest DIY project, aerosol filling machines play a crucial role in delivering these products to consumers. But what exactly are these machines, and how do they work? Buckle up, because we’re diving into everything you need to know about the aerosol filling machine!

What is an Aerosol Filling Machine?

An aerosol filling machine is a specialized piece of equipment designed to fill aerosol cans with products under pressure. These machines can handle a variety of materials, including liquids, creams, and even gases. Think of them as the unsung heroes of the packaging world, efficiently preparing products for a smooth spray delivery. Whether you need a manual aerosol filling machine for small batches or an automatic aerosol filling machine for high-volume production, there’s a machine tailored to your needs.

Types of Aerosol Filling Machines

Manual vs. Automatic vs. Semi-Automatic

- Manual Aerosol Filling Machines: Perfect for small businesses or hobbyists, these machines require the operator to perform most tasks. While they may not be the fastest, they allow for greater control over the filling process.

- Automatic Aerosol Filling Machines: Designed for large-scale production, these machines can fill hundreds of cans per hour with minimal human intervention. They are ideal for manufacturers looking to maximize efficiency.

- Semi-Automatic Aerosol Filling Machines: These machines strike a balance between manual and automatic. They require some human operation but automate key processes, making them a versatile choice for medium-sized businesses.

Standard Aerosol Filling Machine

This type of machine is widely used across various industries. It typically features a simple design and can fill standard aerosol cans with a variety of products. If you’re looking for a reliable workhorse, the standard aerosol filling machine is a solid option.

Bag Valve Aerosol Filling Machine

This machine is designed for filling bags that have a valve. It’s commonly used for products that need to be stored under pressure but require a bag rather than a rigid can. It’s a bit of a niche but crucial for specific applications.

Under-Cap Aerosol Filling Machine

This innovative machine fills aerosol cans from underneath the cap. It allows for quick changes in products and is ideal for manufacturers who produce different types of aerosols on the same line. Flexibility is the name of the game here!

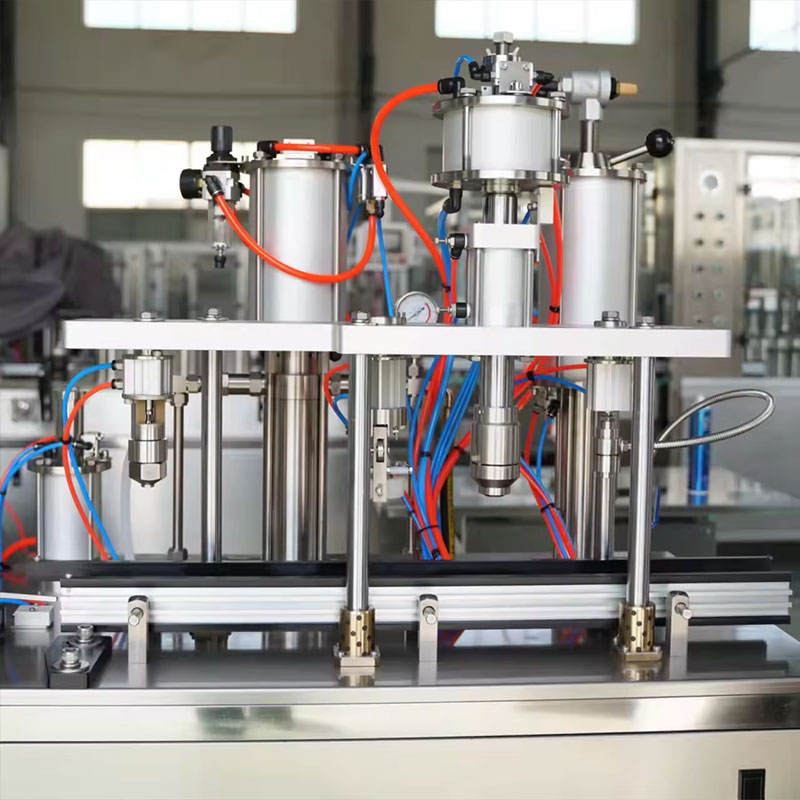

Key Components of Aerosol Filling Machines

Pressure Control Systems

Pressure is everything in aerosol filling. These systems ensure that the correct amount of pressure is maintained during the filling process, preventing leaks and ensuring safety.

Filling Nozzles

The filling nozzles are crucial for accuracy. They help deliver the product into the can in a controlled manner, ensuring that each can is filled to the correct level without overfilling or spilling.

Capping Mechanisms

Once the can is filled, it needs to be sealed. The capping mechanisms secure the cap onto the aerosol can, ensuring that the product remains contained and safe for use.

How Aerosol Filling Machines Work?

The operation of an aerosol can filling machine is a symphony of coordinated actions.

- First, the cans are loaded onto the filling line.

- Next, the machine fills each can with the designated product, controlling the pressure to ensure safety and accuracy.

- After filling, the capping mechanism seals the cans, making them ready for shipping.

It’s a smooth process that combines technology and precision, resulting in perfectly packaged products.

Advantages of Using Aerosol Filling Machines

Aerosol filling machines bring a host of benefits to the table, making them invaluable in modern manufacturing. Let’s dive deeper into the key advantages that make these machines a preferred choice for many businesses.

Increased Production Speed

One of the standout features of aerosol spray can filling machines is their remarkable speed. Designed to operate at high efficiency, these machines can fill multiple cans simultaneously. This capability dramatically boosts production rates compared to traditional manual filling methods, where each can must be filled individually. Imagine the difference: while a manual process might take minutes to fill a few cans, an automatic aerosol filling machine can accomplish the same task in mere seconds. This not only speeds up the overall production cycle but also allows businesses to meet high demand without sacrificing quality.

Consistency and Quality

Aerosol filling machines excel in delivering a uniform fill every single time, which is essential for maintaining quality standards. This level of consistency ensures that every can produced meets the same specifications, reducing the chances of discrepancies that can lead to waste or customer dissatisfaction. Customers expect a reliable product, and when companies can consistently deliver, it builds trust and loyalty.

Enhanced Accuracy and Precision

Aerosol filling machines are engineered to provide precise filling, which is a game changer in manufacturing. Accurate filling not only helps in minimizing product loss but also ensures that each can is filled to the desired level. This precision is particularly important for products that require exact measurements, such as personal care items or automotive sprays. By reducing the likelihood of overfilling or underfilling, manufacturers can maintain tighter control over their inventory and costs, leading to improved profitability.

Reduced Labor Costs

Labor costs can be a significant expense for manufacturers, and automating the filling process can lead to substantial savings. With aerosol filling machines, the need for a large workforce is greatly diminished. Fewer employees are required to manage the filling line, allowing businesses to redirect their resources to other critical areas. This not only streamlines operations but also cuts down on labor-related expenses such as wages, benefits, and training costs.

Common Applications of Aerosol Filling Machines

Personal Care Products

From deodorants to hair sprays, aerosol filling machines are essential in the personal care industry. They help package products that require a fine mist for application.

- Deodorants

- Hair sprays

- Body sprays

- Shaving foams

- Sunscreens

Household Products

Cleaning sprays and air fresheners are often packaged in aerosol cans. These machines ensure that household products are filled accurately and quickly.

- Cleaning sprays

- Air fresheners

- Insecticides

- Fabric fresheners

- Oven cleaners

Automobile Industry

In the automotive sector, aerosol filling machines are used for products like lubricants and cleaning agents, providing convenience and ease of use.

- Engine cleaners

- Lubricants

- Tire inflators

- Brake cleaners

- Spray paints for touch-ups

Food Industry

Some food items, like whipped cream, are also packaged in aerosol cans. Specialized machines ensure that food safety standards are met during filling.

- Whipped cream

- Cooking sprays (e.g., non-stick sprays)

- Cheese whips

- Chocolate mousse

- Sauces in aerosol form

Choosing the Right Aerosol Filling Machine

Selecting the right aerosol filling machine for your business is a crucial decision that can significantly impact your production efficiency and product quality. Here are some key factors to consider to ensure you make the best choice:

Quality and Price

When purchasing an aerosol filling machine, striking the right balance between quality and price is essential. High-quality machines often come with a higher initial investment, but they are designed to be more durable and reliable over time. Investing in a robust, well-engineered machine can save you money in the long run. How? First, a reliable machine minimizes the risk of breakdowns and the associated downtime, which can halt production and lead to lost revenue. Second, efficient machines typically consume less energy and require fewer repairs, further lowering operational costs.

Production Volume

Understanding your production needs is a fundamental step in selecting the right aerosol filling machine. If your business requires high-volume output, an automatic aerosol filling machine is likely the best choice. These machines can handle large quantities swiftly and with precision, ensuring that your production lines keep moving smoothly. On the other hand, if you’re operating on a smaller scale or just starting out, a manual or semi-automatic machine might suffice. These machines are often more affordable and can meet lower production demands effectively.

Your Product Type

Different aerosol products have unique characteristics that require specific handling techniques. For instance, the viscosity of the product, the type of propellant used, and the desired spray pattern all play a role in determining which filling machine is appropriate. Before making a purchase, ensure that the machine you choose is compatible with the specific type of aerosol product you plan to fill. For example, if you’re filling a thicker substance, like foam or gel, you’ll need a machine equipped to handle such materials. Conversely, products that require a fine mist, like personal care sprays, will necessitate precision filling mechanisms. Always consult the manufacturer’s specifications to ensure that the chosen machine aligns with your product requirements.

Manufacturer Reputation

Lastly, take the time to research aerosol filling machines manufacturers. A reputable manufacturer can make a world of difference in your overall experience. Established companies often have a track record of producing reliable machines and can offer better customer support, warranties, and service options. Before committing to a purchase, read reviews and testimonials from other businesses that have used the machines you’re considering. A solid reputation usually indicates a commitment to quality and customer satisfaction. Additionally, reputable manufacturers are more likely to provide valuable technical support and guidance, which can be a lifesaver if you encounter issues during operation or need help with maintenance.

Conclusion

In the world of packaging, aerosol filling machines play a vital role in ensuring that products reach consumers efficiently and safely. Whether you’re looking for a spray can filling machine for personal care items or an aerosol spray paint filling machine for automotive products, understanding the different types, components, and advantages can help you make the right choice. By considering your specific needs and production goals, you can select the perfect aerosol filling machine that will enhance your manufacturing process.

FAQs

1. What types of products can be filled with an aerosol filling machine?

Aerosol filling machines can handle a wide range of products, including personal care items, household cleaners, automotive lubricants, and food products.

2. How do I determine the right type of aerosol filling machine for my business?

Consider your production volume, the type of products you’ll be filling, and whether you prefer manual, semi-automatic, or automatic machines.

3. Are aerosol filling machines safe to use?

Yes, when operated according to manufacturer guidelines, aerosol filling machines are designed with safety features to handle pressurized products safely.

4. Can I use an aerosol filling machine for different types of products?

Some machines are designed for specific products, while others offer flexibility. Always check compatibility before switching product types.

5. What is the average cost of an aerosol filling machine?

The cost can vary widely based on type and features, ranging from a few thousand dollars for manual machines to tens of thousands for advanced automatic systems.